PRODUCTS CATEGORY

- Product Description

-

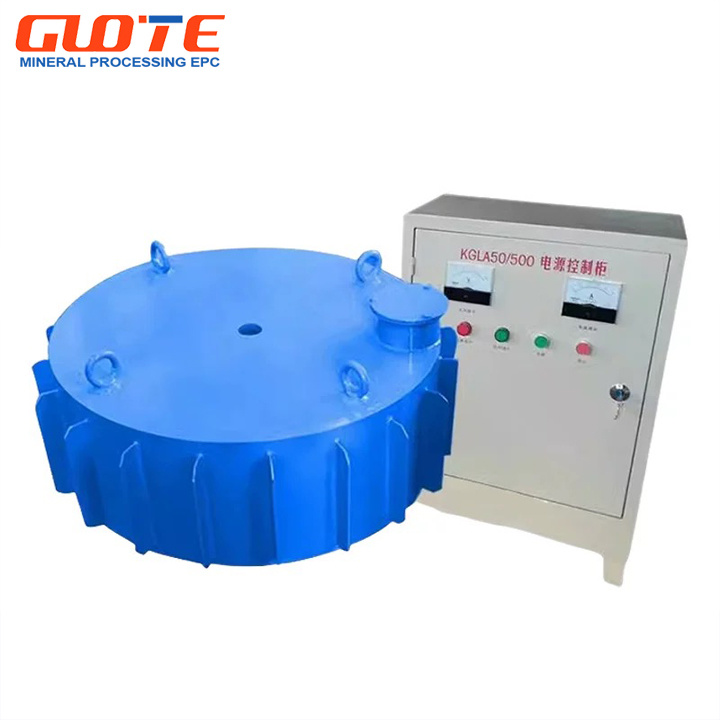

- Commodity name: Permanent Pipeline Self-cleaning Iron Separator

◆ Product Introduction.

RCYZ series iron removers are mainly used for iron removal before cement and slag bagging or bulking. They can be installed at the most needed position on the powder production line to automatically clean and discharge the iron impurities mixed in it. They can effectively avoid equipment "iron jamming" failures and are a new generation of energy-saving and efficient iron removal equipment.

RCYF series iron removers are suitable for removing iron from powdered, granular and block materials in industries such as cement, building materials, chemicals, coal, grain, plastics and refractory materials. They can be connected to conveying pipelines and installed vertically for use.◆ Advantage Features.

Advantages of RCYZ pipeline iron remover:

1. Reasonable structure, small space occupation, easy installation, and can be connected in series in the powder conveying pipeline for use.

2. Adopting high-strength NdFeB permanent magnet, it has high iron removal efficiency and long service life.

3. The iron removal process is completed continuously and automatically, and no special person is required to watch after the equipment is started.

4. It is suitable for closed powder conveying system, no dust escapes during operation, and no pollution to the environment.

5. The iron removal function is continuous and constant, and the mechanical system wear is extremely small.

Advantages of RCYF pipeline iron remover:

1. It uses high-performance strong magnetic material NdFeB as the magnetic source, which has high temperature resistance, stable performance and is not easy to demagnetize.

2. The unique magnetic circuit design and double magnetic pole structure greatly deepen the field strength of the magnetic field area where the material passes, and the suction force is 2-3 times that of ordinary pipeline iron removers.

3. The pipeline is fully sealed and the iron remover is installed externally to avoid damage to the iron remover due to long-term use.

4. It is small in size, light in weight, and can be installed vertically for easy iron removal.

5. It can be designed according to the user's site.◆ Working principle.

Working principle of RCYZ series iron remover : The equipment is connected in series in the material conveying pipeline with an inclination of 45°~75°. When the material passes through the iron remover, the ferromagnetic material in it is adsorbed on the high-strength wear-resistant pipe wall of the pipeline iron remover, and gradually slides to the iron outlet with the movement of the permanent magnet to achieve separation from the material. At the iron outlet, because the permanent magnet moves away in the direction of the circular motion, the ferromagnetic material loses its magnetic attraction and is discharged from the iron outlet under the action of gravity, realizing automatic iron removal of the material.

Working principle of RCYF series iron remover : When working, the ferromagnetic substances mixed in the bulk materials are firmly adsorbed on the iron remover when passing through the strong magnetic field area of the iron remover. To remove the ferromagnetic substances, just open the sealed door. It is installed vertically, which is convenient for iron removal.◆ Technical parameters.

GUOTE MINING

Your reliable supplier

Mine Purification Equipment Engineering Laboratory. The company's products have passed ISO9001 quality system certification, environmental management system certification, occupational health and safety management system certification, EU ce certification, and dozens of national patents. Products are exported to South Korea, India, Southeast Asia, Africa and other countries and regions.

Get A Quote

If you have any questions, please feel free to leave us a message at any time