PRODUCTS CATEGORY

- Product Description

-

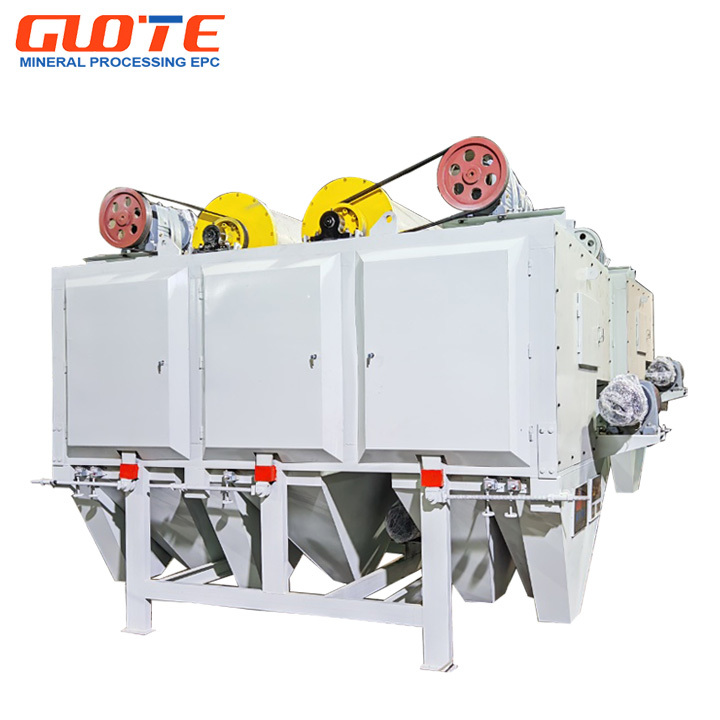

- Commodity name: Permanent Magnet Rotary Wet Drum Magnetic Separator

◆ Product Introduction.

Permanent magnetic drum separator is suitable for mines, Coal preparation plant and other units. Used for weak magnetic field wet separation of fine paticles of strong magnetic minerals, or to remove mixed strong magnetic minerals from non magnetic minerals.The same cylinder of this machine can be equipped with three types of tanks: semi counter flow tank (CTB), counter flow tank(CTN), and forward flow tank (CTS), which are respectively suitable for diferent sorting particle sizes and diferent sorting process requirements. This product adopts computer optimized design, and the magnetic circuit is reasonable and strictly selects the permanent magnet with high Coercivity and high remanence, so as to ensure that the magnetism wil not decrease for a long time, protect the long-term interests of users, and the overall structure is reliable and durable.

◆ Advantage Features.

1、The magnetic circuit design is reasonable, with a large depth of magnetic permeability, and a cross or flipping magnetic field layout.

2、The overall structure is reliable and durable, with multiple slot structures available for selection.

3、The magnetic field strength is customized based on mineral properties, and there are various magnetic field strengths to choose from.

◆ Working principle.

The drum magnetic separator uses a magnetic field to sort materials. Its core principle is the different behaviors of magnetic and non-magnetic materials in a magnetic field. When the material passes through the magnetic drum, the magnetic material is attracted by the magnetic field and adheres to the drum surface, while the non-magnetic material is not affected, thereby achieving the separation of the two. Specific working process: The material enters the sorting area through the feed box and is evenly distributed on the drum surface. The permanent magnet inside the drum generates a strong magnetic field, and the magnetic mineral particles are magnetized and adsorbed on the drum surface and rotate with the drum. When the magnetic mineral particles rotate with the drum to the non-magnetic area, they fall off the drum surface due to the weakening of the magnetic force and the action of water flow (or gravity) and become concentrates. Non-magnetic mineral particles are not affected by the magnetic field and continue to remain in the slurry and are discharged through the tailings tank to become tailings.

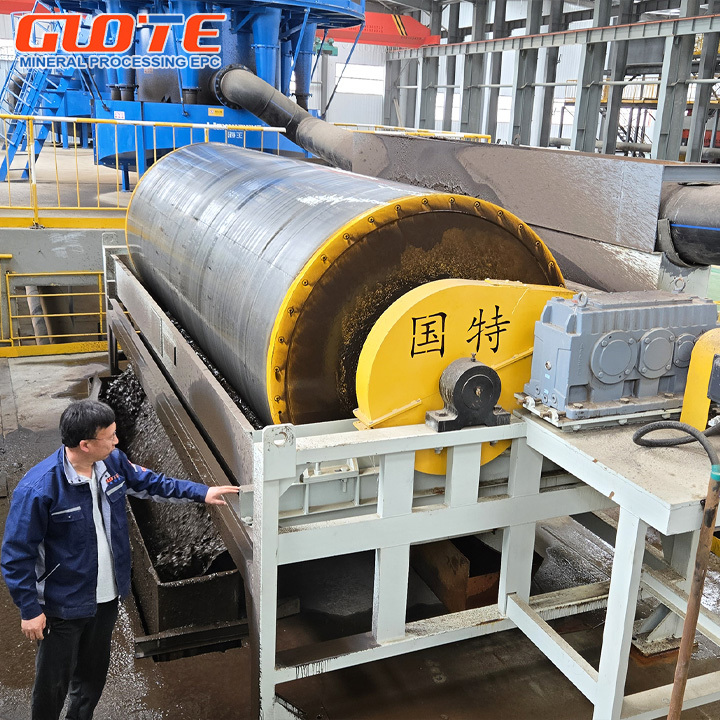

◆ Successful Cases.

◆ Technical parameters.Model

Cylinder size (mm)

Cylinder surface magnetic induction (MT)

Processing capacity

Motor power (kw)

Cylinder speed (r/min)

Total weight of machine (kg)

Average

Sweep constituency

midfield strong magnetic field

t/h

m³/h

CTB(N/S)-712

750*1200

160

200

300-500

5-10

≤ 60

3

35

1500

CTB(N/S)-718

750*1800

160

200

300-500

5-15

≤ 72

3

35

2100

CTB(N/S)-918

900*1800

170

200

300-600

12-22

≤ 90

5.5

28

2900

CTB(N/S)-924

900*2400

170

200

300-600

12-22

≤ 90

5.5

28

3600

CTB(N/S)-1018

1050*1800

180

220

300-700

20-35

≤ 120

7.5

22

4000

CTB(N/S)-1021

1050*2100

180

220

300-700

22-44

≤ 140

7.5

22

4500

CTB(N/S)-1024

1050*2400

180

220

300-700

26-60

≤ 170

7.5

22

5000

CTB(N/S)-1030

1050*3000

180

220

300-700

35-65

≤ 200

11

22

6300

CTB(N/S)-1218

1200*1800

180

220

300-700

35-50

≤ 150

11

19

4900

CTB(N/S)-1224

1200*2400

180

220

300-700

40-55

≤ 200

11

19

5900

CTB(N/S)-1230

1200*1300

180

220

300-700

50-70

≤ 270

11

19

7200

CTB(N/S)-1530

1500*3000

180

220

300-700

100-180

≤ 320

18.5

14

8900

CTB(N/S)-1540

1500*4000

180

220

300-700

115-220

≤ 400

22

14

9900

CTB(N/S)-1545

1500*4500

180

220

300-800

100-130

≤ 650

22

14

10900

CTB(N/S)-1840

1800*4000

180

220

300-800

110-140

≤ 650

30

11

11900

CTB(N/S)-1850

1800*5000

180

220

300-800

150-170

≤ 800

37

11

12900

GUOTE MINING

Your reliable supplier

Mine Purification Equipment Engineering Laboratory. The company's products have passed ISO9001 quality system certification, environmental management system certification, occupational health and safety management system certification, EU ce certification, and dozens of national patents. Products are exported to South Korea, India, Southeast Asia, Africa and other countries and regions.

Get A Quote

If you have any questions, please feel free to leave us a message at any time