PRODUCTS CATEGORY

- Product Description

-

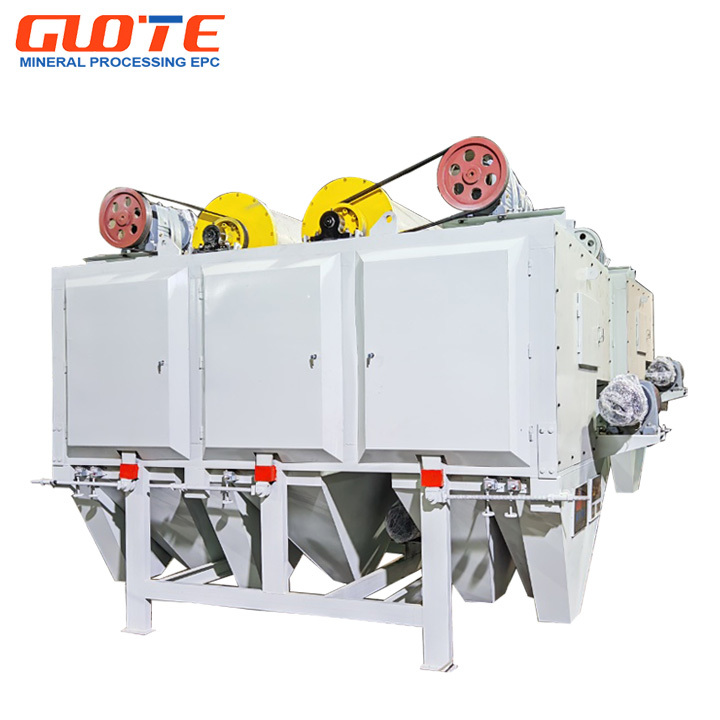

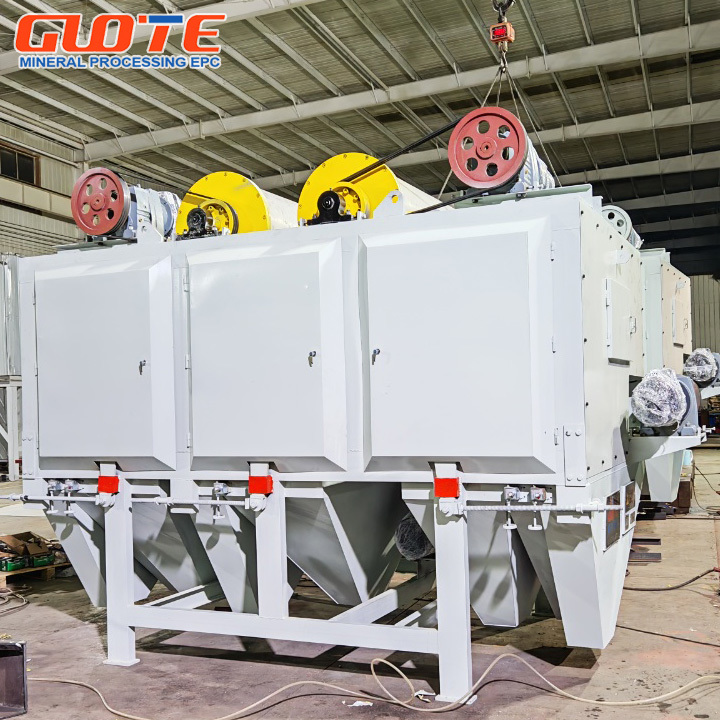

- Commodity name: Metal Mineral Separator

◆ Product Introduction.

Electromagnetic dry powder magnetic separator is particularly suitable for sorting fine-grained mineral powder particles, such as the removal of iron and titanium impurities in non-metallic feldspar powder, quartz powder, kaolin powder and other minerals, as well as the removal and purification of powder materials such as ceramics, chemicals, medicines, electronics, positive and negative electrode materials, graphite, and white carbon black.

◆ Advantage Features.

1. Remove fine crops that are not easy to circulate. Under the action of the vibration motor, raw materials with a volume of less than 200 microns or high humidity can pass through the screen consistently.

2. Processing of high-temperature materials. The standard model can handle raw materials with a temperature of up to 70 degrees Celsius, while the special model can be used to handle raw materials with higher temperatures.

3. The magnetic filter screen is easy to clean. Place a tray at the outlet of the material to recover the separated materials, and turn off the power to demagnetize the screen to facilitate cleaning.

4. Thoroughly separate iron powder and basic materials. Basic materials will never enter the separation box. 5. Simple installation. As long as the bracket is safe and correct, the equipment can be installed arbitrarily.

◆ Working principle.

1. Material feeding: Dry powder materials are fed into the feed port of the magnetic separator evenly and stably through feeding equipment such as vibrating feeders or belt conveyors, and enter the sorting area in an orderly manner. For example, when processing ceramic raw materials, a vibrating feeder is used to feed the dry powder raw materials into the magnetic separator at a uniform speed.

2. Magnetic field establishment: The electromagnetic coil is connected to the current to generate a strong electromagnetic field with adjustable strength as needed. The magnetic field is the key to separating magnetic and non-magnetic materials. When processing ores with different magnetic strengths, the magnetic field strength needs to be adjusted to adapt.

3. Sorting process: When the material enters the sorting area, the magnetic minerals are attracted by the magnetic field force, move in the direction of the magnetic field and adhere to magnetic media such as magnetic rollers and magnetic plates; non-magnetic minerals are not affected or are affected by very little magnetic force, and rely on mechanical forces such as gravity and inertia to continue moving along the original path. For example, when processing alumina powder containing iron impurities, the iron impurities are adsorbed as magnetic substances, and the alumina continues to move forward.

4. Non-magnetic material discharge: non-magnetic materials are discharged from the special non-magnetic material outlet of the magnetic separator.

5. Magnetic material collection: magnetic materials adsorbed on the magnetic medium leave the magnetic field area as the magnetic medium rotates or moves, and fall off due to the loss of magnetic force, and are discharged from the magnetic material outlet to complete the separation.

6. Circular operation: the magnetic medium continues to work in the separation area. After completing the sorting of one batch of materials, the next batch is processed immediately to achieve continuous and uninterrupted magnetic separation operation.◆ Successful Cases.

GUOTE MINING

Your reliable supplier

Mine Purification Equipment Engineering Laboratory. The company's products have passed ISO9001 quality system certification, environmental management system certification, occupational health and safety management system certification, EU ce certification, and dozens of national patents. Products are exported to South Korea, India, Southeast Asia, Africa and other countries and regions.

Get A Quote

If you have any questions, please feel free to leave us a message at any time