PRODUCTS CATEGORY

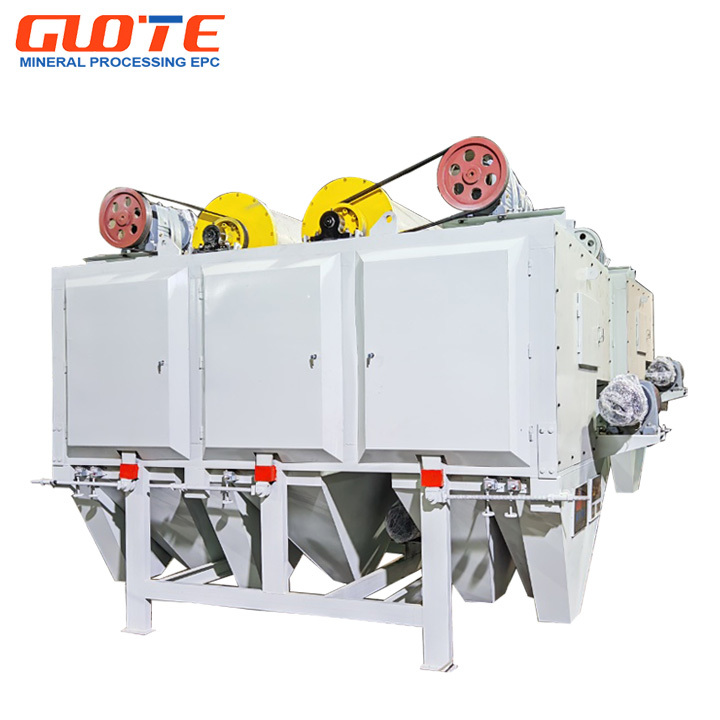

Electromagnetic Powder Magnetic Separator

The core advantage of the Dry powder electromagnetic separator lies in its powerful magnetic system. The strong magnetic field generated by the electromagnetic coil can efficiently adsorb and separate ferromagnetic impurities in powdered materials to ensure the accuracy and efficiency of sorting.

- Product Description

-

- Commodity name: Electromagnetic Powder Magnetic Separator

The core advantage of the Dry powder electromagnetic separator lies in its powerful magnetic system. The strong magnetic field generated by the electromagnetic coil can efficiently adsorb and separate ferromagnetic impurities in powdered materials to ensure the accuracy and efficiency of sorting.

◆ Product Introduction.

GDF high-field Dry powder electromagnetic separator has the advantages of high magnetic field strength, simple installation, high temperature resistance, convenient cleaning, and so on. It can design different field strengths according to different ore properties. When non-magnetic minerals are separated from the magnetic field, the minerals are well separated from the magnetic cylinder under the action of gravity.

Application areas: Ceramics, glass, refractory materials, abrasives and limonite, and other weak magnetic ore dry pre-selection, dry pre-selection of manganese ore.

◆ Advantage Features.

1. Excellent separation performance: The core advantage of the electromagnetic powder magnetic separator lies in its powerful magnetic system. The strong magnetic field generated by the electromagnetic coil can efficiently adsorb and separate ferromagnetic impurities in powdered materials to ensure the accuracy and efficiency of sorting. Its magnetic force can be flexibly adjusted according to demand to adapt to different materials and processing conditions to ensure the best separation effect.

2. Efficient and stable working principle: The equipment adopts the principle of electromagnetic field, and forms a stable and adjustable magnetic force by precisely controlling the current to perform continuous and stable material sorting. The powdered material enters the magnetic separation area through the hopper. Under the action of the strong magnetic field, the ferromagnetic impurities are adsorbed onto the magnetic drum, and the cleaned material passes smoothly to complete the separation process.

3. Energy saving and environmental protection: The design of the electromagnetic powder magnetic separator fully considers the needs of energy saving and environmental protection. The electromagnetic system has low power consumption, reduces energy dependence, and reduces operating costs. At the same time, the closed design of the equipment effectively prevents dust leakage and ensures the cleanliness and safety of the operating environment.

4. Strong and durable structural design: The magnetic separator is made of high-quality materials, with a compact structure, corrosion resistance, wear resistance, and can withstand long-term high-intensity work. The electromagnetic coil is made of high-magnetic permeability material to ensure the lasting stability of the magnetic force and extend the service life of the equipment.

5. Easy operation and convenient maintenance: The operation interface of the electromagnetic powder magnetic separator is simple and intuitive, and users can adjust the magnetic strength and working mode according to actual needs. Regular inspection and maintenance of the equipment can extend its service life, and its structural design makes maintenance work more convenient and reduces downtime.

◆ Application Areas.

It is mainly used to separate ferromagnetic impurities from powder or fine particle materials to ensure the purity of the product and the safety of production equipment. The following are the six major application areas of this equipment:

1. Metallurgical industry: used for the treatment of ore powder, waste, smelting slag, etc., to remove ferromagnetic impurities, ensure metal recovery rate, improve product purity in the smelting process, and reduce equipment wear.2. Chemical industry: In the production of chemical products such as fertilizers, plastics, pigments, etc., electromagnetic powder magnetic separators can effectively remove metal impurities in raw materials, ensure the stability of the production process, and the high purity of the final product.

3. Food industry: used for the treatment of powdered food raw materials (such as flour, powdered sugar, etc.), to remove ferromagnetic impurities, ensure food safety, and prevent metal impurities from causing equipment damage or product contamination.

4. Building materials industry: In the production process of building materials such as cement, ceramics, and glass, remove ferromagnetic impurities in raw materials to ensure product quality, avoid pollution, and improve production efficiency.

5. Mining and mining industry: Suitable for the treatment of ore powder, electromagnetic powder magnetic separators can separate ferromagnetic substances from ore to ensure the purity and efficiency of ore extraction.

6. Environmental protection industry: In environmental protection fields such as waste recycling and garbage classification, electromagnetic powder magnetic separators can efficiently remove ferromagnetic metals from waste, improve the recovery rate of waste, and reduce environmental pollution.

Through these applications, Dry powder electromagnetic separators can not only improve production efficiency, but also effectively improve product quality. They are indispensable and important equipment in many industries.

◆ Successful Cases.

◆ Technical parameters.

Specifications

Standard type

high magnetic type

GDF-150

GDF-250

GDF-300

GDF-150H

GDF-250H

GDF-300H

Processing capacity (t/h)

5

15

20

5

15

20

Weight (kg)

200

400

450

800

1200

1400

Outer diameter of filter screen (mm)

145

245

295

145

245

295

Number of filter screens

33

35

35

33

35

35

Amount of insulating oil (l)

30

50

50

60

70

120

Size of control panel (mm)

300*400*540

350*500*600

GUOTE MINING

Your reliable supplier

Mine Purification Equipment Engineering Laboratory. The company's products have passed ISO9001 quality system certification, environmental management system certification, occupational health and safety management system certification, EU ce certification, and dozens of national patents. Products are exported to South Korea, India, Southeast Asia, Africa and other countries and regions.

Get A Quote

If you have any questions, please feel free to leave us a message at any time