PRODUCTS CATEGORY

- Product Description

-

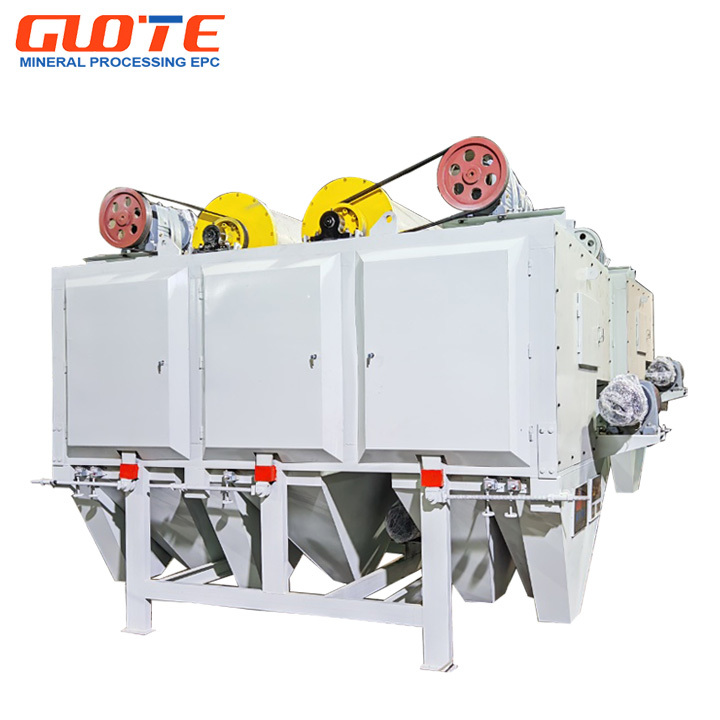

- Commodity name: Permanent Magnet Dry Rotary Drum Magnetic Separator

◆ Product Introduction.

It can be used to remove iron pollutants from powdery or fine-grained materials, and is used for the purification of non-metallic minerals such as refractory materials, glass, ceramics, abrasives, etc., the removal of impurities in chemicals, grains and non-magnetic metal ores, and the dry pre-selection of hematite and limonite.

◆ Advantage Features.

1. Equipped with a vibrating feeder to feed evenly and remove debris continuously and automatically.

2. Rare earth permanent magnet material is used as a magnetic source, with a large magnetic penetration depth and strong suction.

3. The new type of compensating magnetic pole type magnetic system makes the magnetic field intensity higher and the gradient larger.

4. It can be made into a two-cylinder or multi-cylinder type, and the magnetic force can be selected (1000~10000Gs).

5. The whole machine is maintenance-free and safe and reliable to use.◆ Working principle.

The drum magnetic separator uses a magnetic field to sort materials. Its core principle is the different behaviors of magnetic and non-magnetic materials in a magnetic field. When the material passes through the magnetic drum, the magnetic material is attracted by the magnetic field and adheres to the drum surface, while the non-magnetic material is not affected, thereby achieving the separation of the two. Specific working process: The material enters the sorting area through the feed box and is evenly distributed on the drum surface. The permanent magnet inside the drum generates a strong magnetic field, and the magnetic mineral particles are magnetized and adsorbed on the drum surface and rotate with the drum. When the magnetic mineral particles rotate with the drum to the non-magnetic area, they fall off the drum surface due to the weakening of the magnetic force and the action

of gravity and become concentrates. Non-magnetic mineral particles are not affected by the magnetic field and continue to remain in the slurry and are discharged through the tailings tank to become tailings.◆ Successful Cases.

◆ Technical parameters.

Model

Overall dimensions (mm)

Roller length (mm)

Roller diameter (mm)

Magnetic induction intensity (GS)

Number of rollers (pcs)

Drum speed (r/min)

Producti-vity (t/h)

Material size (mm)

Motor power (kw)

GCXII-120-Ⅰ

2006x1100x1450

1000-10000

1

17-82

≤5

≤10

3

GCXII-120-Ⅱ

2274x1700x2250

1200

600

2

≤6

≤10

5.5

GCXII-120-Ⅲ

2880x1700x2950

1200

600

3

≤8

≤10

3*3

GCXII-140-Ⅰ

2206x1100x1450

1400

608

1

≤6

≤10

4

GCXII-140-Ⅱ

2274x2000x2250

1400

608

2

≤8

≤10

7.5

GCXII-140-Ⅲ

2800x2000x2850

1400

608

3

≤10

≤10

4*3

GCXII-160-Ⅰ

1960x1274x1650

1600

800

1

≤10

≤12

5.5

GCXII-160-Ⅱ

2674x2160x2850

1600

800

2

≤12

≤12

5.5*2

GCXII-160-Ⅲ

3120x2160x3700

1600

800

3

≤15

≤15

5.5*3

GUOTE MINING

Your reliable supplier

Mine Purification Equipment Engineering Laboratory. The company's products have passed ISO9001 quality system certification, environmental management system certification, occupational health and safety management system certification, EU ce certification, and dozens of national patents. Products are exported to South Korea, India, Southeast Asia, Africa and other countries and regions.

Get A Quote

If you have any questions, please feel free to leave us a message at any time