PRODUCTS CATEGORY

Permanent Magnet Dry Roller Magnetic Separator

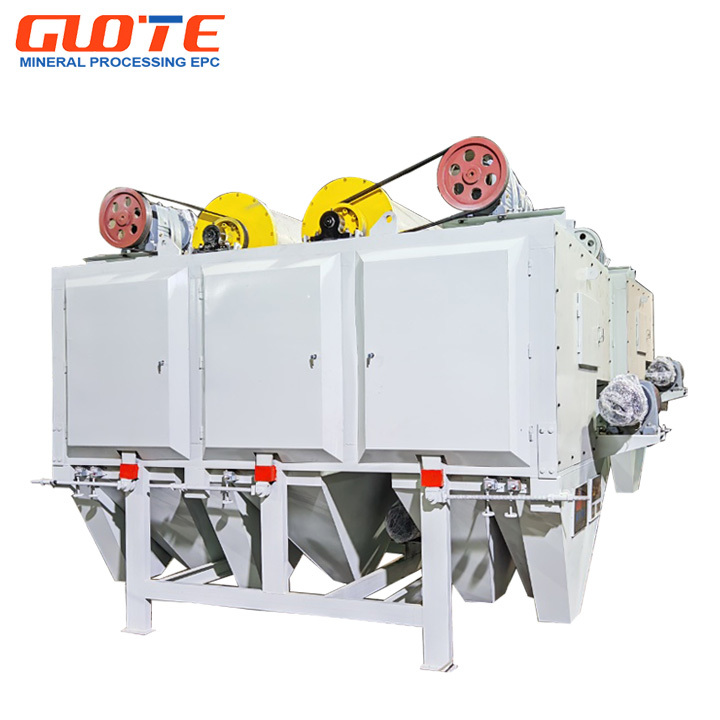

The Dry roller magnetic separator is a highly efficient ore sorting device widely used in the mining, metallurgy, and environmental protection industries. Through its powerful magnetic field, it effectively separates ferromagnetic and non-magnetic materials in ore, achieving high-precision purification.

- Product Description

-

- Commodity name: Permanent Magnet Dry Roller Magnetic Separator

The Dry roller magnetic separator is a highly efficient ore sorting device widely used in the mining, metallurgy, and environmental protection industries. Through its powerful magnetic field, it effectively separates ferromagnetic and non-magnetic materials in ore, achieving high-precision purification.

◆ Product Introduction.

Particles or coarse powder materials clear weak magnetic impurities, used in ceramics, glass, refractory materials, abrasives, and other non-metallic minerals, chemical, food, biological purification, and hematite, limonite, and other weak magnetic ore dry pre-selection, dry beneficiation of manganese ore. The Dry roller magnetic separator is a highly efficient ore sorting device widely used in the mining, metallurgy, and environmental protection industries. Through its powerful magnetic field, it effectively separates ferromagnetic and non-magnetic materials in ore, achieving high-precision purification.

The device features a roller-type design with an automatic cleaning function, ensuring stability and efficiency during continuous operation. Utilizing advanced magnetic materials and precision design, this magnetic separator not only achieves high sorting efficiency but also reduces energy consumption, meeting modern environmental standards. Its compact structure and easy operation make it ideal for material sorting in dry environments, making it an ideal choice for mining processing.

Application areas: Ceramics, glass, refractory materials, abrasives and limonite, and other weak magnetic ore dry pre-selection, dry pre-selection of manganese ore.◆ Advantage Features.

1. The equipment has a dust removal port, and dust is discharged in a centralized manner to meet environmental protection requirements.

2. Automatic cleaning of weak magnetic oxides can ensure long-term trouble-free operation.

3. The controllable feeding system ensures the uniformity of the material when it flows through the magnetic field area. The conveyor belt used by the magnetic roller is made of special materials with good wear resistance.

4. The magnetic roller adopts a concentrated magnetic composite magnetic system, and the magnetic field strength can reach 15000GS, with a higher gradient.

5. The magnetic system of the magnetic drum can be made into a flipping type, and the removal rate is greatly improved. The speed of the drum and the magnetic roller is frequency-controlled to adapt to wider particle size and output requirements.

6. The drum adopts a new type of compensation magnetic machine type magnetic system, and the magnetic field strength can reach 8000GS, with a higher magnetic field strength and stronger suction.

7. The reasonable combination of a permanent magnetic drum and a permanent magnetic roller has a better iron removal effect.

◆ Working principle.

The granular material falls into the vibrating feeding device through the feeding funnel and is evenly vibrated to the working area of the permanent magnetic roller. The magnetic particles are firmly adsorbed on the surface of the magnetic roller. After being brought into the non-magnetic field area, they are discharged through the magnetic material discharge port. Under the action of gravity and inertia, the non-magnetic material falls into the magnetic roller mechanism for the next level of magnetic separation. The conveyor belt transports the material to the magnetic roller. Under the action of the magnetic field of up to 18000GS, the weak magnetic particles are firmly adsorbed on the surface of the magnetic roller, and then sent to the non-magnetic field area by the conveyor belt and discharged through the magnetic material discharge port. The non-magnetic material continues to enter the next level of the magnetic roller mechanism. After multiple selections, the non-magnetic particles are discharged through the non-magnetic material discharge port at the front of the equipment.

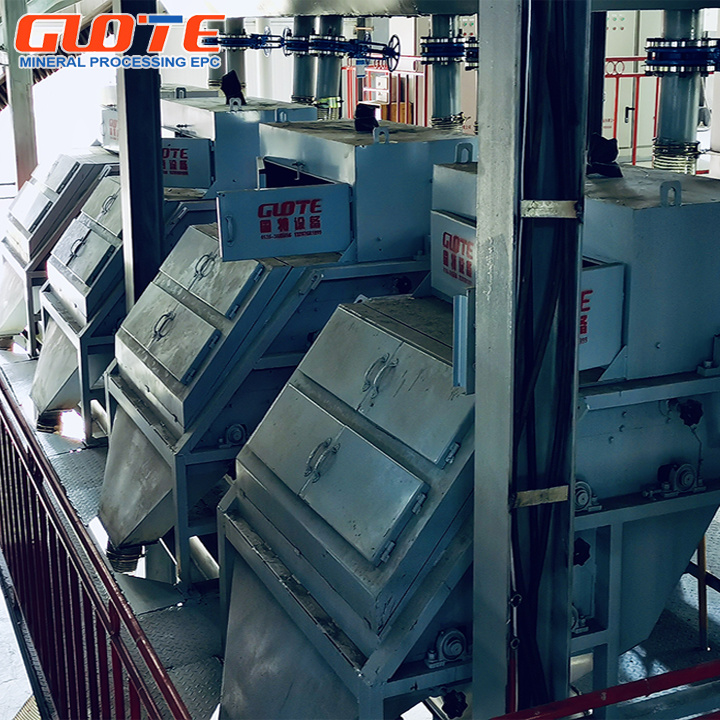

◆ Successful Cases.

◆ Technical parameters.

GUOTE MINING

Your reliable supplier

Mine Purification Equipment Engineering Laboratory. The company's products have passed ISO9001 quality system certification, environmental management system certification, occupational health and safety management system certification, EU ce certification, and dozens of national patents. Products are exported to South Korea, India, Southeast Asia, Africa and other countries and regions.

Get A Quote

If you have any questions, please feel free to leave us a message at any time