Maximizing Efficiency with Durable Vertical Ring High Gradient Magnetic Separators

Durable vertical ring high gradient magnetic separators are advanced devices specifically designed to separate magnetic materials from non-magnetic ones through the application of strong magnetic fields. These separators are particularly beneficial in industries like mineral processing, recycling, and waste management, where the efficient separation of materials is crucial for operational effectiveness and product quality.

The key feature of these magnetic separators is their vertical ring design, which allows for enhanced magnetic field strength and separation efficiency. The high gradient refers to the ability of the separator to create a steep magnetic field gradient, which increases the force exerted on magnetic particles, enabling the separation of fine materials that are typically challenging to process. This is especially relevant in applications where only a minute amount of magnetic materials need to be extracted from a bulk of non-magnetic feed.

One of the primary advantages of durable vertical ring high gradient magnetic separators is their robustness. Built with high-quality materials, these separators are designed to withstand harsh operational conditions, including abrasive materials and varying temperatures. This durability ensures a longer lifespan and reduced maintenance costs, which ultimately contributes to lower operational expenses for companies utilizing this technology.

Efficiency is another significant aspect of these magnetic separators. Their unique design allows for a continuous feed operation, minimizing downtime during material processing. This feature is particularly beneficial in high-throughput applications where maximizing productivity is essential. The ability to achieve high separation rates while maintaining the integrity of non-magnetic materials makes these separators an essential tool for manufacturers aiming to optimize their processes.

Moreover, the flexibility of durable vertical ring high gradient magnetic separators allows them to be tailored to specific applications. Depending on the type of material being processed and the desired purity levels, adjustments can be made to the magnetic field strength and separator configuration. This adaptability makes them suitable for a wide range of industries, from mining to recycling.

In summary, durable vertical ring high gradient magnetic separators play a vital role in improving the efficiency and effectiveness of material separation processes. Their robust construction, high operational efficiency, and adaptability to various applications make them an indispensable asset in the manufacturing and processing machinery sector. By investing in such advanced technologies, businesses can enhance their operational capabilities and achieve better outcomes in their material processing endeavors.

The key feature of these magnetic separators is their vertical ring design, which allows for enhanced magnetic field strength and separation efficiency. The high gradient refers to the ability of the separator to create a steep magnetic field gradient, which increases the force exerted on magnetic particles, enabling the separation of fine materials that are typically challenging to process. This is especially relevant in applications where only a minute amount of magnetic materials need to be extracted from a bulk of non-magnetic feed.

One of the primary advantages of durable vertical ring high gradient magnetic separators is their robustness. Built with high-quality materials, these separators are designed to withstand harsh operational conditions, including abrasive materials and varying temperatures. This durability ensures a longer lifespan and reduced maintenance costs, which ultimately contributes to lower operational expenses for companies utilizing this technology.

Efficiency is another significant aspect of these magnetic separators. Their unique design allows for a continuous feed operation, minimizing downtime during material processing. This feature is particularly beneficial in high-throughput applications where maximizing productivity is essential. The ability to achieve high separation rates while maintaining the integrity of non-magnetic materials makes these separators an essential tool for manufacturers aiming to optimize their processes.

Moreover, the flexibility of durable vertical ring high gradient magnetic separators allows them to be tailored to specific applications. Depending on the type of material being processed and the desired purity levels, adjustments can be made to the magnetic field strength and separator configuration. This adaptability makes them suitable for a wide range of industries, from mining to recycling.

In summary, durable vertical ring high gradient magnetic separators play a vital role in improving the efficiency and effectiveness of material separation processes. Their robust construction, high operational efficiency, and adaptability to various applications make them an indispensable asset in the manufacturing and processing machinery sector. By investing in such advanced technologies, businesses can enhance their operational capabilities and achieve better outcomes in their material processing endeavors.

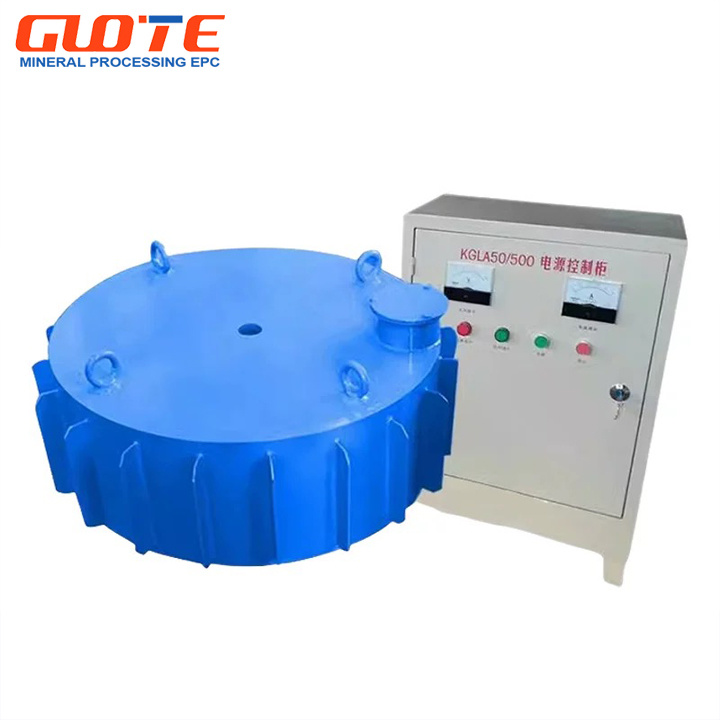

durable Vertical ring high gradient magnetic separator

Previous Page

Previous Page

Related Products

Related News