The Role of Advanced Wet Type Glass Sand Processing in Global Supply Chains

The Role of Advanced Wet Type Glass Sand Processing in Global Supply Chains

Introduction: Understanding Wet Type Glass Sand Processing

The global supply chain is an intricate system where various components work together to deliver products efficiently and effectively. In this context, **wet type glass sand processing** emerges as a critical player. This technology is essential for producing high-quality glass products, ranging from windows to containers. In this article, we delve into the significance of advanced wet type glass sand processing and its profound impact on global supply chains.

What is Wet Type Glass Sand Processing?

Wet type glass sand processing involves the use of water to separate and refine silica sand. This process enhances the purity and quality of the glass sand, making it suitable for diverse applications in the glass manufacturing industry. By utilizing advanced technologies, manufacturers can achieve a higher yield of high-quality products while minimizing waste.

The Importance of Silica Sand in Glass Manufacturing

Silica sand is the primary raw material for glass production. Its composition affects the durability, clarity, and overall performance of glass products. The **wet processing method** ensures that the silica sand is devoid of impurities, which is crucial for producing high-quality glass.

Key Techniques in Wet Type Processing

Several techniques are employed in wet type glass sand processing, including:

- **Washing**: This initial step removes contaminants and clay particles from the sand.

- **Classification**: Sand particles are sorted based on size, ensuring uniformity.

- **Desliming**: Fine particles, such as silt and clay, are eliminated to enhance the quality of the glass sand.

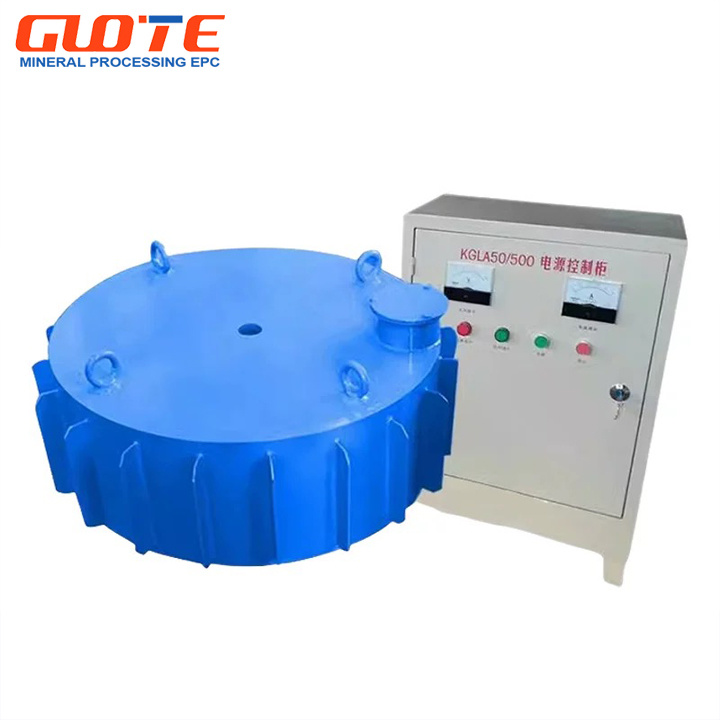

- **Magnetic Separation**: This technique removes iron and other magnetic impurities, which can affect the color and quality of the final product.

Benefits of Advanced Wet Type Glass Sand Processing

The implementation of advanced wet type glass sand processing brings numerous benefits to manufacturers and the global supply chain:

1. Enhanced Product Quality

Advanced processing techniques significantly improve the purity and quality of glass sand. Higher quality raw materials lead to better glass products, which meet stringent industry standards.

2. Increased Efficiency and Yield

Modern wet processing systems utilize automation and cutting-edge technology, enhancing operational efficiency. This increased efficiency results in higher yields and reduced production costs.

3. Environmental Sustainability

By adopting wet processing methods, manufacturers can minimize dust and other emissions associated with traditional dry processing. This contributes to a more sustainable manufacturing process that aligns with global environmental standards.

4. Flexibility in Production

Advanced wet type processing systems allow for flexibility in product lines. Manufacturers can easily adjust their processes to accommodate different glass specifications or respond to market demands.

5. Improved Safety Standards

The wet processing method reduces dust exposure for workers, creating a safer working environment. Improved safety standards are crucial for maintaining a healthy workforce.

The Role of Wet Type Glass Sand Processing in Global Supply Chains

The impact of wet type glass sand processing extends beyond individual manufacturing plants. Its integration into global supply chains plays a vital role in ensuring efficiency and product quality.

Streamlining Supply Chains

By producing high-quality glass sand, manufacturers can streamline their supply chains. Consistent raw material quality leads to fewer disruptions and a more reliable production schedule. This efficiency is crucial for meeting global demands.

Reducing Lead Times

Advanced wet processing technologies allow manufacturers to reduce lead times significantly. Quicker production cycles translate to faster delivery of products to market, aligning with the just-in-time production models prevalent in many industries.

Meeting Global Demand for Quality Glass Products

As the demand for glass products continues to rise globally, manufacturers must ensure they can meet this demand with high-quality materials. Advanced wet type glass sand processing is essential for producing the quality required to compete in international markets.

Trends Shaping Advanced Wet Type Glass Sand Processing

The industry is evolving, and several trends are emerging that will shape the future of advanced wet type glass sand processing.

1. Adoption of Automation and AI

Innovations in automation and artificial intelligence are changing the landscape of wet processing. Smart systems can monitor and adjust processes in real-time, optimizing production efficiency and quality.

2. Emphasis on Sustainability

With increasing awareness of environmental issues, manufacturers are prioritizing sustainable practices. Advanced wet type processing methods that reduce waste and energy consumption are becoming the norm.

3. Global Collaboration and Innovation

The global nature of supply chains encourages collaboration across borders. Manufacturers are partnering with technology providers to innovate and enhance processing techniques.

4. Enhanced Data Analytics

Data analytics is playing a crucial role in refining processing methods. By analyzing production data, manufacturers can identify inefficiencies and improve their overall processes.

Challenges in Implementing Advanced Wet Type Glass Sand Processing

While the benefits are substantial, manufacturers face challenges when implementing advanced wet type glass sand processing techniques.

1. Initial Investment Costs

The transition to advanced processing systems requires significant investment in technology and training. This initial cost may be a barrier for some manufacturers, particularly smaller operations.

2. Skill Gaps in the Workforce

The adoption of advanced technologies requires a skilled workforce. Manufacturers must invest in training programs to ensure their employees are equipped to handle new systems.

3. Supply Chain Disruptions

Global supply chains are susceptible to disruptions from various factors, including geopolitical tensions and natural disasters. Manufacturers must develop strategies to mitigate these risks.

Future Outlook for Advanced Wet Type Glass Sand Processing

The future of advanced wet type glass sand processing looks promising as the industry continues to evolve. Key areas of focus will include:

1. Continuous Innovation

Ongoing research and development will drive innovation in processing techniques, leading to even higher product quality and efficiency.

2. Expansion into New Markets

As global demand for glass products grows, manufacturers will seek opportunities to expand into new markets. Wet type processing will be essential for meeting the specific requirements of these markets.

3. Enhanced Regulatory Compliance

As environmental regulations become stricter, manufacturers must ensure their processes comply with new standards. Advanced wet type processing methods can help meet these regulatory requirements.

FAQs: Advanced Wet Type Glass Sand Processing

1. What is the primary benefit of wet type glass sand processing?

The primary benefit is the production of high-purity glass sand, which leads to superior quality glass products.

2. How does wet processing differ from dry processing?

Wet processing utilizes water to separate and refine sand, while dry processing relies on mechanical methods that can generate dust and impurities.

3. Is wet type glass sand processing environmentally friendly?

Yes, it minimizes dust emissions and waste, contributing to a more sustainable manufacturing process.

4. What industries rely on wet type glass sand processing?

Industries such as construction, automotive, and packaging heavily rely on high-quality glass products derived from wet processed sand.

5. How can manufacturers stay competitive in the glass sand market?

By adopting advanced wet processing technologies, focusing on quality, and responding swiftly to market demands, manufacturers can maintain a competitive edge.

Conclusion

In conclusion, advanced wet type glass sand processing is pivotal in enhancing the efficiency and quality of global supply chains. As manufacturers continue to embrace this technology, the benefits in terms of product quality, sustainability, and operational efficiency become increasingly evident. By navigating the challenges and capitalizing on emerging trends, the industry is poised for a bright future, one that aligns with the growing global demand for high-quality glass products. Through innovation and collaboration, advanced wet type glass sand processing will remain a cornerstone of the manufacturing landscape.

advanced Wet type glass sand processing line

Related Products

Related News