PRODUCTS CATEGORY

- Product Description

-

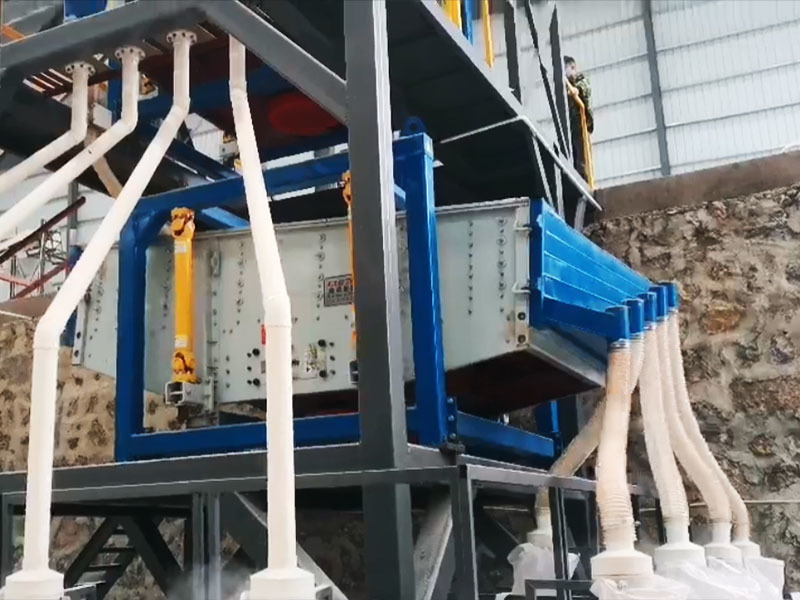

- Commodity name: Square Swing Screen

◆ Product Introduction.

Square swing screen is a kind of high-efficiency screening equipment with high precision and large output specially developed by national special equipment. Through the square swing screen, the vibrator vibrates and swings and is transmitted to the screen surface, so that the materials are quickly dispersed in the front of the screen machine, thus achieving the purpose of efficient screening.

Application areas

Widely used in chemical, metallurgy, non-ferrous metals, non-ferrous metals, food, abrasive and other industries.◆ Advantage Features.

1. Complete types, complete types, single-layer, multi-layer optional, discharge port 360 "arbitrary rotation, suitable for continuous assembly line production.

2. Unique grid structure: the use of wave-shaped steel plate bending, increase the probability of the ball collision screen, to achieve a better sub-effect.

3. Stainless steel screen: The use of stainless steel wear-resistant screen increases the service life of the screen, greatly reducing the frequency of replacing the screen and the cost of use.

4. Special elastic ball: the use of special elastic ball, its elasticity is better than other manufacturers of inferior ball, can greatly reduce the blockage of the screen hole, better promote the screening effect.

5. Precise positioning, precise positioning, professional engineer design, a variety of styles, can effectively screen particles, powder, slurry materials, which can be better applied to the screening of fracturing sand.

6. Reasonable design and long service life: reasonable design, simple structure, stable operation; energy saving and environmental protection, long service life, high screening accuracy, simple operation, in line with the production process requirements of domestic users.◆ Working principle.

Square swing screen can also be called reciprocating vibrating screen and precision vibrating screen. The vibration force generated by its motor drive device is an inertial force with a certain regular change in direction around a fixed axis. Its essence is the reciprocating inertial force formed by the rotation of eccentric wheel around the fixed axis. According to the structural characteristics and working principle of the swing screen, its screen surface is generally horizontal or slightly inclined arrangement "inclination angle is 0-5).

The working principle of the square swing screen is as follows: after the swing screen is started, the shaking body of the equipment, that is, the screen box, moves back and forth under the action of inertial force, and the screen box and the screen surface are connected for periodic shaking, so that the materials on the screen surface make directional jumping movement together with the screen box. During this period, the material smaller than the sieve hole falls to the lower layer through the sieve hole and becomes the material under the sieve. The material larger than the sieve hole diameter is discharged from the discharge port after continuous tumbling and overlooking movement, thus completing the screening work.◆ Successful Cases.

GUOTE MINING

Your reliable supplier

Mine Purification Equipment Engineering Laboratory. The company's products have passed ISO9001 quality system certification, environmental management system certification, occupational health and safety management system certification, EU ce certification, and dozens of national patents. Products are exported to South Korea, India, Southeast Asia, Africa and other countries and regions.

Get A Quote

If you have any questions, please feel free to leave us a message at any time