Maximizing Efficiency: How the Newest High Frequency Dewatering Screen Transforms Mining Operations

Maximizing Efficiency: How the Newest High Frequency Dewatering Screen Transforms Mining Operations

The mining industry is constantly evolving, driven by the need for improved efficiency, reduced costs, and enhanced environmental sustainability. One of the most significant advancements in this field is the introduction of high frequency dewatering screens. These machines have revolutionized the way mining operations manage water removal and material recovery. In this article, we will explore how the newest high frequency dewatering screens are transforming mining operations, maximizing efficiency, and driving overall success.

Table of Contents

- Introduction to High Frequency Dewatering Screens

- What is a High Frequency Dewatering Screen?

- How Do High Frequency Dewatering Screens Work?

- Benefits of High Frequency Dewatering Screens

- Applications of High Frequency Dewatering Screens in the Mining Industry

- Case Studies: Success Stories in Mining Operations

- The Future of High Frequency Dewatering Screens in Mining

- Conclusion

- FAQs About High Frequency Dewatering Screens

Introduction to High Frequency Dewatering Screens

Mining operations are notorious for their high water consumption and the challenges posed by excess water in the processing of minerals. Water management has become a critical factor in maintaining operational efficiency and compliance with environmental regulations. High frequency dewatering screens have emerged as a solution to these challenges, offering enhanced performance in the separation of solids from liquids.

What is a High Frequency Dewatering Screen?

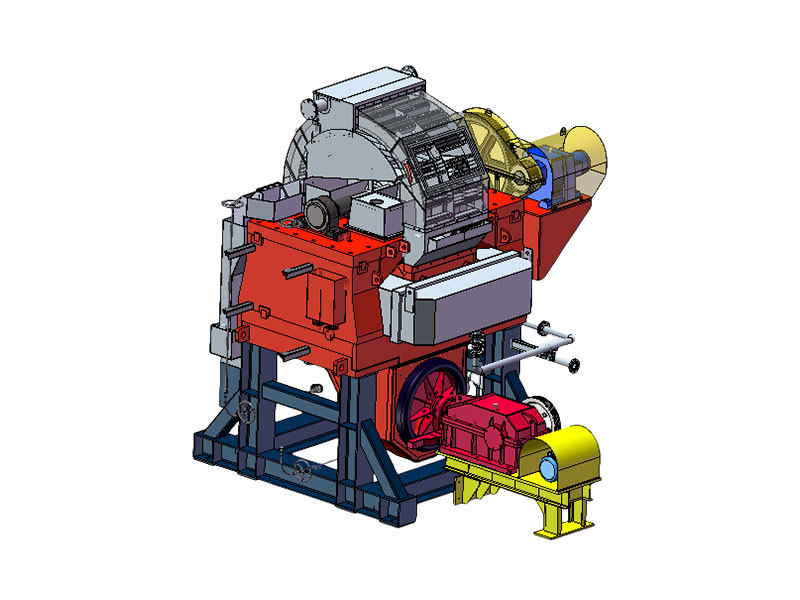

A high frequency dewatering screen is a specialized type of vibrating screen designed to efficiently separate water from slurry materials. Unlike traditional dewatering methods, high frequency screens operate at significantly higher frequencies, allowing for more effective and rapid water removal. These screens utilize a combination of high-frequency vibrations and advanced screen fabric technology to achieve superior dewatering performance.

Key Components of High Frequency Dewatering Screens

To understand how high frequency dewatering screens work, it is essential to familiarize ourselves with their key components:

- Screen Box: The structure that holds the screen media and provides support during operation.

- Vibrating Mechanism: A motor-driven mechanism that generates high-frequency vibrations to facilitate the separation process.

- Screen Media: The material used to create the screening surface, which can vary in size and type depending on the application.

- Underflow and Overflow Channels: Channels designed to manage the flow of slurry and water during the dewatering process.

How Do High Frequency Dewatering Screens Work?

The operation of a high frequency dewatering screen can be broken down into several key steps:

1. Slurry Introduction

The slurry material, consisting of water and solids, is fed onto the screen surface. This initial step is crucial for effective separation.

2. Vibration Induction

Once the slurry is on the screen, the vibrating mechanism activates, generating high-frequency vibrations. This agitation causes the water to move through the screen media while forcing the solids to remain on the surface.

3. Water Removal

As the water passes through the screen, it collects in the underflow channels. The effectiveness of this process is greatly enhanced by the high-frequency vibrations, which prevent blinding and promote continuous drainage.

4. Solid Material Discharge

After the water has been removed, the solid material is discharged from the screen, ready for further processing or stockpiling.

Benefits of High Frequency Dewatering Screens

High frequency dewatering screens offer numerous advantages that contribute to enhanced operational efficiency in mining:

1. Improved Water Recovery

These screens are designed to maximize water recovery, ensuring that minimal water is lost during the dewatering process. This not only conserves water but also reduces waste management costs.

2. Enhanced Material Quality

By effectively removing excess water, high frequency dewatering screens improve the quality of the final product. Drier materials are easier to handle and transport, leading to higher market value.

3. Increased Throughput

The high-frequency operation allows for increased throughput, meaning that more material can be processed in a shorter period. This leads to higher overall productivity and profitability.

4. Reduced Environmental Impact

With improved water management capabilities, high frequency dewatering screens contribute to a reduced environmental footprint. They help mining operations comply with regulations regarding water discharge and waste management.

5. Lower Operating Costs

By enhancing efficiency and reducing water consumption, these screens ultimately lower the operating costs associated with mining operations. This cost-effectiveness makes them an attractive investment for mining companies.

Applications of High Frequency Dewatering Screens in the Mining Industry

The versatility of high frequency dewatering screens allows for their application across various mining sectors:

1. Coal Mining

In coal mining operations, high frequency dewatering screens are used to efficiently remove water from coal slurry, ensuring that the product meets market specifications.

2. Mineral Processing

Mineral processing plants utilize these screens to separate valuable minerals from waste material, enhancing recovery rates and reducing water usage.

3. Aggregate Production

In the production of aggregates, dewatering screens help achieve the desired moisture content for materials like sand and gravel, facilitating better handling and application.

4. Industrial Minerals

High frequency dewatering screens are essential for the processing of industrial minerals, where precise water removal is critical to maintaining product quality.

5. Gold and Precious Metals Mining

In gold and precious metals mining, these screens help maximize recovery rates by efficiently dewatering concentrate, ensuring that more valuable material is captured.

Case Studies: Success Stories in Mining Operations

Several mining companies have successfully integrated high frequency dewatering screens into their operations, resulting in remarkable improvements:

Case Study 1: Coal Mine Efficiency Enhancement

A leading coal mining company implemented high frequency dewatering screens to address issues with water management. By doing so, they achieved a 30% increase in water recovery and reduced overall operational costs by 15% within the first year.

Case Study 2: Mineral Processing Improvement

Another mineral processing plant adopted high frequency screens, resulting in a 25% increase in throughput and a significant improvement in the quality of the final product. Their investment in this technology paid off within six months as they saw increased sales and reduced waste management costs.

Case Study 3: Aggregate Production Optimization

An aggregate producer incorporated high frequency dewatering screens to enhance the moisture content of their gravel products. This led to improved handling and application, resulting in a 20% increase in customer satisfaction and repeat business.

The Future of High Frequency Dewatering Screens in Mining

The future of high frequency dewatering screens looks promising, with ongoing advancements in technology and materials. Innovations such as smart sensors and automation are expected to further enhance the efficiency of these machines. As mining operations continue to prioritize sustainability and efficiency, high frequency dewatering screens will play a pivotal role in shaping the industry's future.

Conclusion

High frequency dewatering screens represent a significant leap forward in mining technology, transforming the way operations manage water removal and material recovery. Their ability to maximize efficiency, enhance product quality, and reduce operational costs makes them indispensable in today’s competitive mining industry. As we move towards a more sustainable future, the role of high frequency dewatering screens will undoubtedly grow, offering exciting possibilities for mining companies worldwide.

FAQs About High Frequency Dewatering Screens

1. What is the primary function of a high frequency dewatering screen?

The primary function of a high frequency dewatering screen is to efficiently separate water from slurry materials, enhancing the recovery of solids in mining processes.

2. How do high frequency screens differ from traditional dewatering methods?

High frequency screens operate at significantly higher frequencies, allowing for more effective and rapid water removal compared to traditional dewatering methods.

3. What industries benefit most from high frequency dewatering screens?

Industries such as coal mining, mineral processing, aggregate production, and precious metals mining benefit greatly from high frequency dewatering screens.

4. Can high frequency dewatering screens reduce environmental impact?

Yes, these screens help improve water management and reduce waste, contributing to a lower environmental footprint for mining operations.

5. Are high frequency dewatering screens cost-effective?

Yes, while the initial investment may be significant, the operational efficiency and cost savings achieved typically lead to a rapid return on investment.

newest High frequency dewatering screen

Related Products

Related News