Understanding the Wet Type Silica Sand Processing Line: A Comprehensive Overview

Silica sand is a crucial material used in various industries, ranging from construction to glass manufacturing. The wet type silica sand processing line is designed to enhance the purity and quality of silica sand through specific processing techniques. This line typically involves several stages, including washing, classification, and dewatering, which collectively work to produce high-quality silica sand suitable for commercial applications.

The first step in the wet type silica sand processing line is the washing stage. Here, raw silica sand is subjected to water, which helps in the removal of impurities such as clay, silt, and other contaminants. The washing process not only improves the visual appearance of the sand but also enhances its physical properties, making it more suitable for various applications. Effective washing is crucial, as it lays the groundwork for subsequent processes.

Following the washing phase, the classification process comes into play. This step involves using a combination of mechanical and hydraulic methods to separate the silica sand based on particle size. By employing techniques such as hydrocyclones or vibrating screens, operators can ensure that sand particles of a specific size are isolated, allowing for the production of uniform and consistently graded silica sand. This uniformity is essential for industries such as foundries and glass manufacturers, where specific grain sizes are required.

Once the sand has been classified, the next step is dewatering. Excess water is removed from the sand through various methods, including centrifugation or vacuum drying. The goal of dewatering is to attain the desired moisture content that is optimal for storage and transportation. Proper dewatering not only enhances the quality of the final product but also reduces the costs associated with handling and shipping.

Moreover, the wet type silica sand processing line offers environmental advantages. By utilizing water in the processing stages, this method minimizes dust emissions, which can be harmful to both workers and the surrounding environment. Additionally, water used in the process can often be recycled, contributing to sustainable practices within the industry.

In summary, the wet type silica sand processing line plays a vital role in producing high-quality silica sand by employing a series of effective processing techniques. From washing and classification to dewatering, each stage is designed to enhance the purity and performance of silica sand, making it suitable for various industrial applications. As industries continue to evolve, the demand for high-quality silica sand will only increase, making it crucial for manufacturers to invest in efficient processing lines that can meet these needs. Understanding these processes is essential for anyone involved in the manufacturing and processing of silica sand.

The first step in the wet type silica sand processing line is the washing stage. Here, raw silica sand is subjected to water, which helps in the removal of impurities such as clay, silt, and other contaminants. The washing process not only improves the visual appearance of the sand but also enhances its physical properties, making it more suitable for various applications. Effective washing is crucial, as it lays the groundwork for subsequent processes.

Following the washing phase, the classification process comes into play. This step involves using a combination of mechanical and hydraulic methods to separate the silica sand based on particle size. By employing techniques such as hydrocyclones or vibrating screens, operators can ensure that sand particles of a specific size are isolated, allowing for the production of uniform and consistently graded silica sand. This uniformity is essential for industries such as foundries and glass manufacturers, where specific grain sizes are required.

Once the sand has been classified, the next step is dewatering. Excess water is removed from the sand through various methods, including centrifugation or vacuum drying. The goal of dewatering is to attain the desired moisture content that is optimal for storage and transportation. Proper dewatering not only enhances the quality of the final product but also reduces the costs associated with handling and shipping.

Moreover, the wet type silica sand processing line offers environmental advantages. By utilizing water in the processing stages, this method minimizes dust emissions, which can be harmful to both workers and the surrounding environment. Additionally, water used in the process can often be recycled, contributing to sustainable practices within the industry.

In summary, the wet type silica sand processing line plays a vital role in producing high-quality silica sand by employing a series of effective processing techniques. From washing and classification to dewatering, each stage is designed to enhance the purity and performance of silica sand, making it suitable for various industrial applications. As industries continue to evolve, the demand for high-quality silica sand will only increase, making it crucial for manufacturers to invest in efficient processing lines that can meet these needs. Understanding these processes is essential for anyone involved in the manufacturing and processing of silica sand.

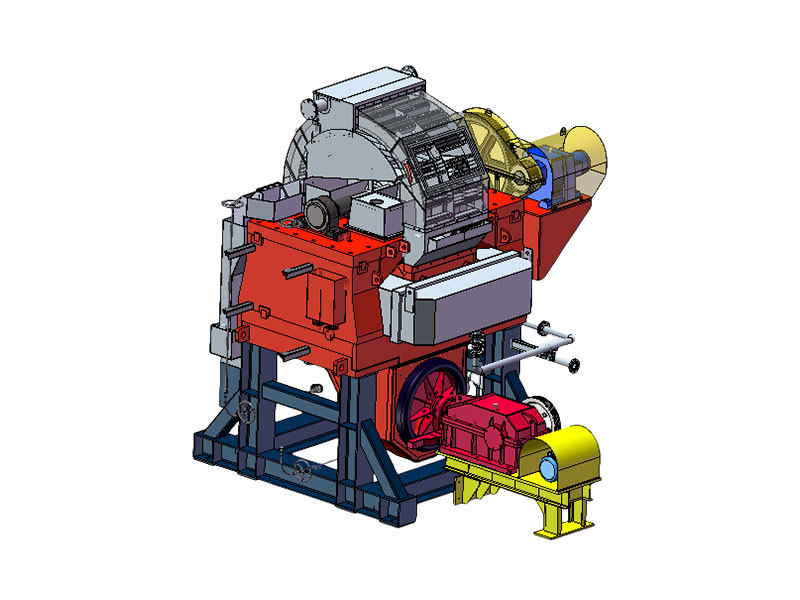

Wet type silica sand processing line

Related Products

Related News