Ilmenite processing line

As one of the main titanium minerals, ilmenite has significant value due to its wide application in multiple industrial fields.

- Product Description

- Advantage Features

- Working principle

- Technical parameters

- Successful Cases

-

- Commodity name: Ilmenite processing line

As one of the main titanium minerals, ilmenite has significant value due to its wide application in multiple industrial fields.

As one of the main titanium minerals, ilmenite has significant value due to its wide application in multiple industrial fields. In order to effectively extract ilmenite from ores, various beneficiation methods can be used, including gravity separation, magnetic separation, flotation, and electrostatic separation, as well as their combined applications.

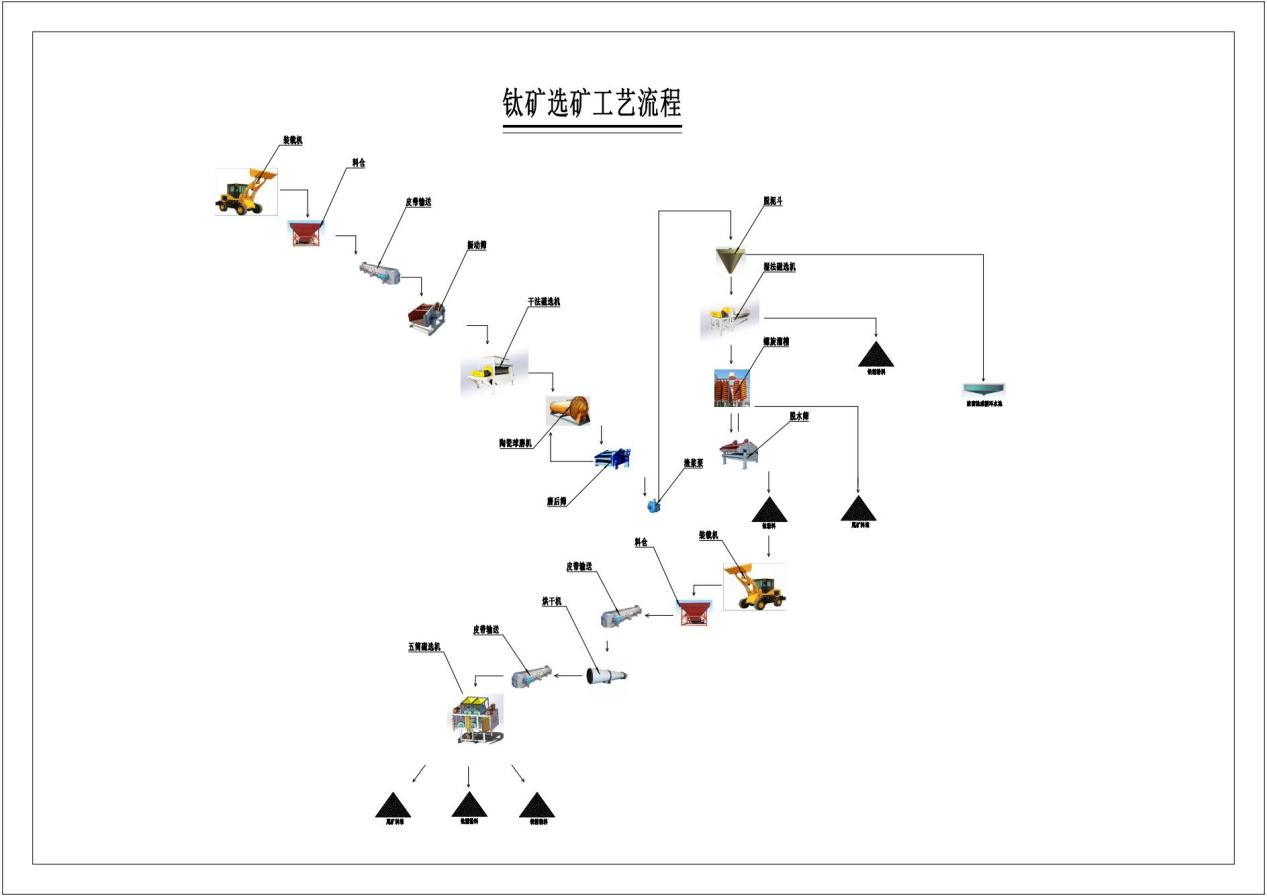

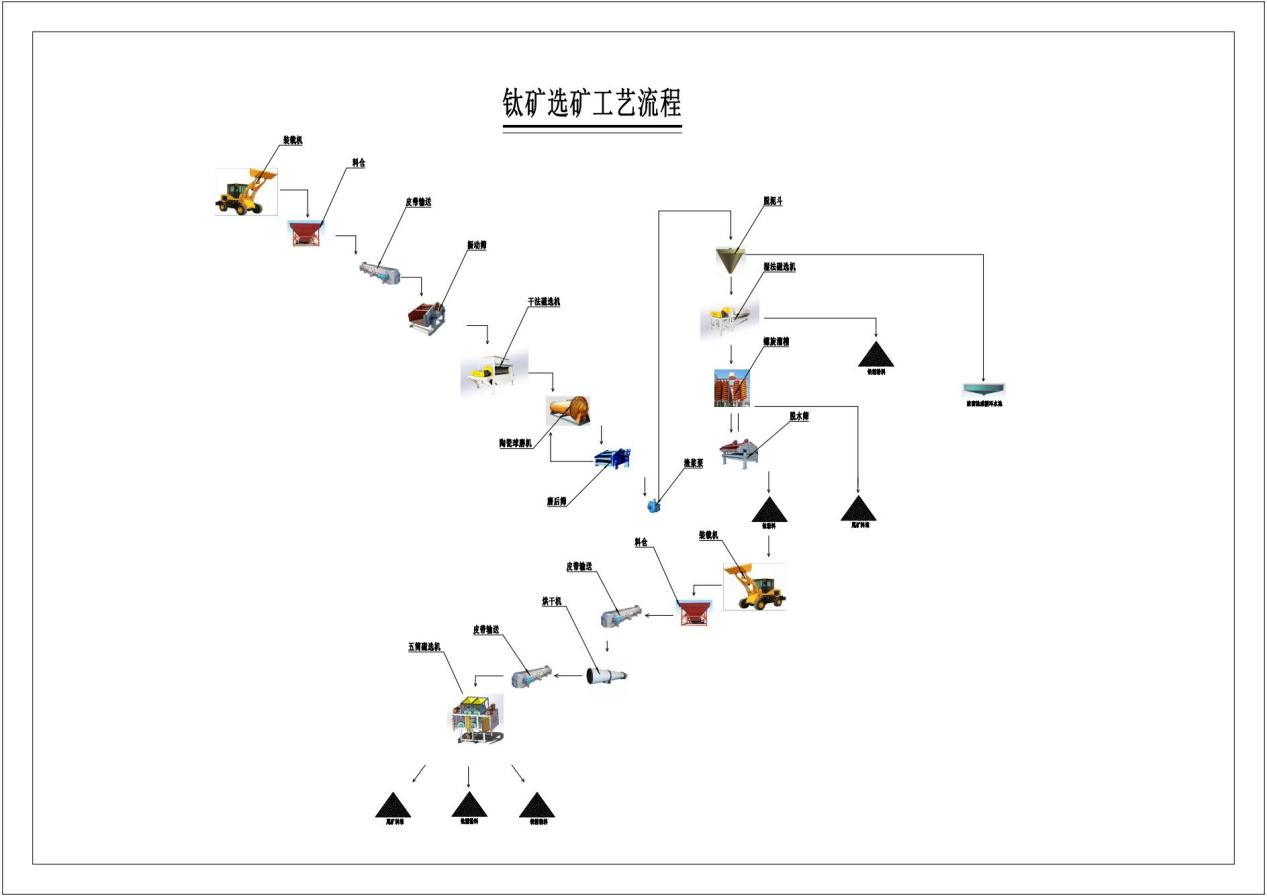

Technological Process

-

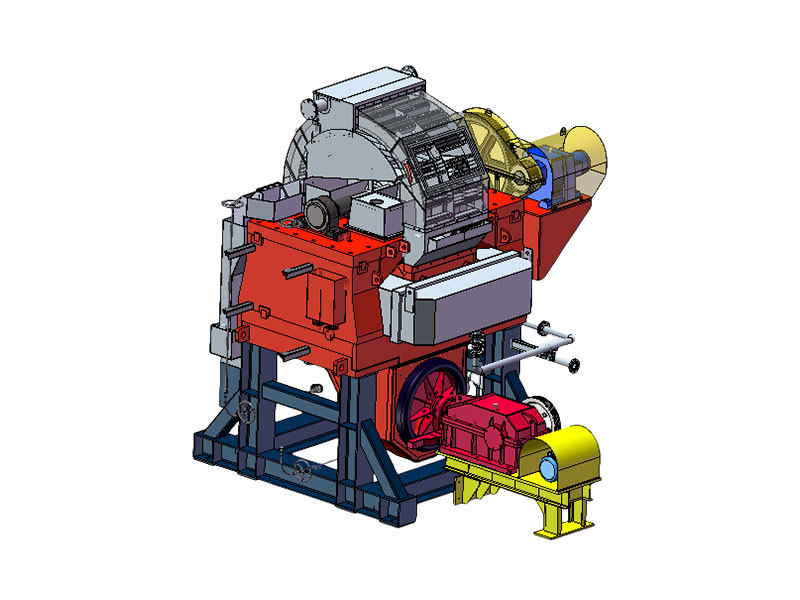

1、 Dry throwing magnetic separation and wet magnetic separation reselection of ilmenite

Dry throwing magnetic separation and wet magnetic separation are two commonly used methods for extracting ilmenite ore in mines. Simply put, dry beneficiation of ilmenite is the use of physical methods to process ilmenite, while wet beneficiation involves adding water to the dry beneficiation process for selection.

2、 Characteristics and process of iron ore dry selection

The dry selection of ilmenite mainly relies on the influence of minerals such as quartz on the separation of ilmenite. The main processes include crushing, screening, and magnetic separation. The characteristics of this method are simple process, low cost, and wide applicability.

The process of dry selection of ilmenite is generally as follows:

1. Use mechanical crushing and screening technology to separate iron ore into particles of different sizes.

2. Conduct a preliminary selection of medium field strength for the separated particles, mainly using a medium field strong magnetic separator to separate the iron concentrate.

3. Then, a high field magnetic separator is used for secondary screening to obtain high-grade titanium concentrate and low-grade tailings.

3、 Characteristics and process of wet beneficiation of ilmenite

Compared with dry selection, wet selection has a more complex process but higher separation efficiency. The main feature of wet selection is the use of water for liquid-solid separation of ore, achieving the purpose of separating iron ore.

The wet selection process generally includes stages such as crushing, washing, magnetic separation, reselection, and dehydration. This method is widely used for processing low-grade and refractory ilmenite.

The process of wet selection of ilmenite is generally as follows:

1. Grind the ilmenite into fine particles of the desired mesh size.

2. Use a slurry pump to send the slurry to a wet drum magnetic separator to separate most of the iron powder in ilmenite.

3. Re selection, using a spiral chute to separate the titanium iron powder.

4. Finally, the separated titanium iron slurry is further dehydrated and enters the reservoir

5. The drained titanium iron powder enters the dryer for drying treatment

6. The dried titanium iron powder enters a five cylinder magnetic separator to separate titanium concentrate powder, iron concentrate powder, and some tailings.

4、 Comparison between dry and wet selection of ilmenite

Although both dry and wet beneficiation of ilmenite are basic methods for mineral processing, and their processes are roughly the same, there are still some differences between the two in practical applications. The comparison between dry selection and wet selection is as follows:

1. Wet selection has better separation effect;

2. Dry selection has low costs, but the output will be affected by the condition of the materials;

3. Wet selection can handle titanium iron ores that are difficult to select, have high water content, and high viscosity.

In short, both dry and wet selection of iron ore have their own advantages and disadvantages, and the appropriate method should be selected according to the specific situation. -

1. Process method for reselection of ilmenite

Due to the higher specific gravity of titanium minerals compared to non-metallic gangue minerals, re-election can be used for the separation of ilmenite. This method is suitable for both coarse-grained and fine-grained group impregnated ilmenite. The general process of reselection is to use reselection equipment such as jigs, spiral chutes, and shaking tables to remove gangue minerals and sludge after coarse and medium crushing. It has the characteristics of low production cost and less environmental pollution.

2. Magnetic Separation Process for Titanium Ore

Titanium iron ore belongs to weakly magnetic minerals. Under the same volume, the volume magnetization intensity of titanium iron ore is much higher than that of vein minerals. Through strong magnetic separation, effective separation of titanium iron ore and vein minerals can be achieved, achieving enrichment. It is commonly used in the selection process and has good separation effects on both coarse-grained and fine-grained titanium iron ore. The magnetic field strength selected for magnetic separation varies depending on the type of ilmenite ore.

Titanium iron ore mostly exists in the form of complex solid solutions in mineral deposits, which can easily produce titanium iron ore flakes with higher magnetization coefficients. The difference in magnetization between titanium iron ore and gangue increases, making it easy to separate by magnetic separation. Some ilmenite sand ores contain a large amount of impurities and sludge. After primary grinding, weak magnetic separation can be used to separate the iron ore, and then medium strong magnetic separation can be used to select the titanium ore, in order to improve the recovery and utilization rate of the ore.

3. The flotation process method of ilmenite

The flotation method plays a crucial role in the extraction process of ilmenite. It includes several different methods such as conventional flotation, flocculation flotation, agglomeration flotation, and carrier flotation. The conventional flotation method mainly uses collectors such as oleic acid and its soaps, oxidized paraffin soap, and tar oil, and improves the collection performance by adjusting the temperature, increasing the oxygen content, or adding emulsifiers. It is suitable for the selection of primary titanium ore and fine-grained titanium iron ore.

Flocculation flotation method can be divided into selective flocculation flotation method and hydrophobic flocculation flotation method. The former selectively flocculates fine-grained ilmenite by adding coagulants such as polyacrylamide, while the latter utilizes the hydrophobic interaction between mineral particles to make them agglomerate and float, which has certain advantages for the recovery of fine-grained ilmenite.

4. Process method for electro selection of ilmenite

The electric selection method is mainly used to process titanium iron ores containing non-conductive impurities such as titanium pyroxene, and is a critical operation for titanium concentrate.

5. Joint beneficiation process method for ilmenite

The processing method of ilmenite is determined by its own properties. When the composition of ilmenite is complex, it is difficult to achieve good separation results using a single beneficiation method. Therefore, a combined process flow is required. Common ilmenite combined process flows include magnetic separation flotation method, magnetic separation reselection method, gravity separation flotation method, gravity separation magnetic separation flotation electric separation method, etc.

Product Description

As one of the main titanium minerals, ilmenite has significant value due to its wide application in multiple industrial fields. In order to effectively extract ilmenite from ores, various beneficiation methods can be used, including gravity separation, magnetic separation, flotation, and electrostatic separation, as well as their combined applications.

Technological Process

Advantage Features

1、 Dry throwing magnetic separation and wet magnetic separation reselection of ilmenite

Dry throwing magnetic separation and wet magnetic separation are two commonly used methods for extracting ilmenite ore in mines. Simply put, dry beneficiation of ilmenite is the use of physical methods to process ilmenite, while wet beneficiation involves adding water to the dry beneficiation process for selection.

2、 Characteristics and process of iron ore dry selection

The dry selection of ilmenite mainly relies on the influence of minerals such as quartz on the separation of ilmenite. The main processes include crushing, screening, and magnetic separation. The characteristics of this method are simple process, low cost, and wide applicability.

The process of dry selection of ilmenite is generally as follows:

1. Use mechanical crushing and screening technology to separate iron ore into particles of different sizes.

2. Conduct a preliminary selection of medium field strength for the separated particles, mainly using a medium field strong magnetic separator to separate the iron concentrate.

3. Then, a high field magnetic separator is used for secondary screening to obtain high-grade titanium concentrate and low-grade tailings.

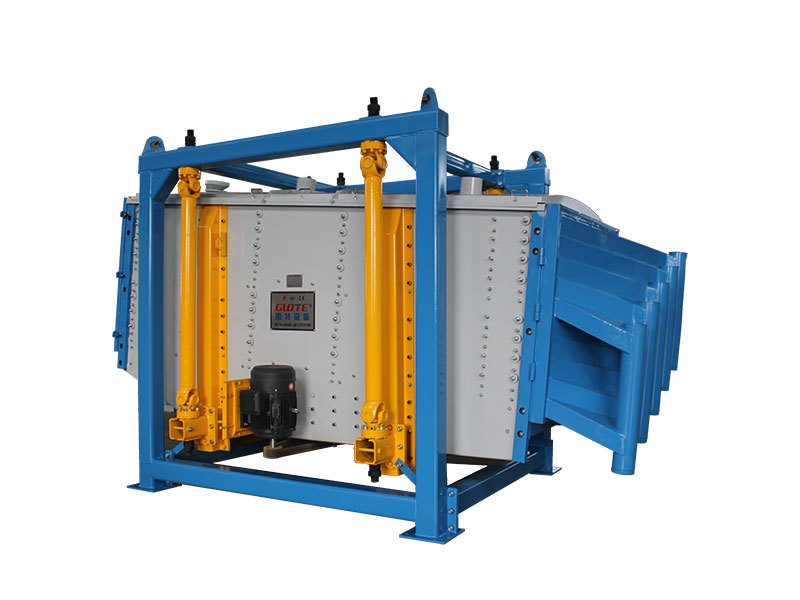

3、 Characteristics and process of wet beneficiation of ilmenite

Compared with dry selection, wet selection has a more complex process but higher separation efficiency. The main feature of wet selection is the use of water for liquid-solid separation of ore, achieving the purpose of separating iron ore.

The wet selection process generally includes stages such as crushing, washing, magnetic separation, reselection, and dehydration. This method is widely used for processing low-grade and refractory ilmenite.

The process of wet selection of ilmenite is generally as follows:

1. Grind the ilmenite into fine particles of the desired mesh size.

2. Use a slurry pump to send the slurry to a wet drum magnetic separator to separate most of the iron powder in ilmenite.

3. Re selection, using a spiral chute to separate the titanium iron powder.

4. Finally, the separated titanium iron slurry is further dehydrated and enters the reservoir

5. The drained titanium iron powder enters the dryer for drying treatment

6. The dried titanium iron powder enters a five cylinder magnetic separator to separate titanium concentrate powder, iron concentrate powder, and some tailings.

4、 Comparison between dry and wet selection of ilmenite

Although both dry and wet beneficiation of ilmenite are basic methods for mineral processing, and their processes are roughly the same, there are still some differences between the two in practical applications. The comparison between dry selection and wet selection is as follows:

1. Wet selection has better separation effect;

2. Dry selection has low costs, but the output will be affected by the condition of the materials;

3. Wet selection can handle titanium iron ores that are difficult to select, have high water content, and high viscosity.

In short, both dry and wet selection of iron ore have their own advantages and disadvantages, and the appropriate method should be selected according to the specific situation.

Working principle

1. Process method for reselection of ilmenite

Due to the higher specific gravity of titanium minerals compared to non-metallic gangue minerals, re-election can be used for the separation of ilmenite. This method is suitable for both coarse-grained and fine-grained group impregnated ilmenite. The general process of reselection is to use reselection equipment such as jigs, spiral chutes, and shaking tables to remove gangue minerals and sludge after coarse and medium crushing. It has the characteristics of low production cost and less environmental pollution.

2. Magnetic Separation Process for Titanium Ore

Titanium iron ore belongs to weakly magnetic minerals. Under the same volume, the volume magnetization intensity of titanium iron ore is much higher than that of vein minerals. Through strong magnetic separation, effective separation of titanium iron ore and vein minerals can be achieved, achieving enrichment. It is commonly used in the selection process and has good separation effects on both coarse-grained and fine-grained titanium iron ore. The magnetic field strength selected for magnetic separation varies depending on the type of ilmenite ore.

Titanium iron ore mostly exists in the form of complex solid solutions in mineral deposits, which can easily produce titanium iron ore flakes with higher magnetization coefficients. The difference in magnetization between titanium iron ore and gangue increases, making it easy to separate by magnetic separation. Some ilmenite sand ores contain a large amount of impurities and sludge. After primary grinding, weak magnetic separation can be used to separate the iron ore, and then medium strong magnetic separation can be used to select the titanium ore, in order to improve the recovery and utilization rate of the ore.

3. The flotation process method of ilmenite

The flotation method plays a crucial role in the extraction process of ilmenite. It includes several different methods such as conventional flotation, flocculation flotation, agglomeration flotation, and carrier flotation. The conventional flotation method mainly uses collectors such as oleic acid and its soaps, oxidized paraffin soap, and tar oil, and improves the collection performance by adjusting the temperature, increasing the oxygen content, or adding emulsifiers. It is suitable for the selection of primary titanium ore and fine-grained titanium iron ore.

Flocculation flotation method can be divided into selective flocculation flotation method and hydrophobic flocculation flotation method. The former selectively flocculates fine-grained ilmenite by adding coagulants such as polyacrylamide, while the latter utilizes the hydrophobic interaction between mineral particles to make them agglomerate and float, which has certain advantages for the recovery of fine-grained ilmenite.

4. Process method for electro selection of ilmenite

The electric selection method is mainly used to process titanium iron ores containing non-conductive impurities such as titanium pyroxene, and is a critical operation for titanium concentrate.

5. Joint beneficiation process method for ilmenite

The processing method of ilmenite is determined by its own properties. When the composition of ilmenite is complex, it is difficult to achieve good separation results using a single beneficiation method. Therefore, a combined process flow is required. Common ilmenite combined process flows include magnetic separation flotation method, magnetic separation reselection method, gravity separation flotation method, gravity separation magnetic separation flotation electric separation method, etc.

Technical parameters

Successful Cases

Related Products

GUOTE MINING

Your reliable supplier

Mine Purification Equipment Engineering Laboratory. The company's products have passed ISO9001 quality system certification, environmental management system certification, occupational health and safety management system certification, EU ce certification, and dozens of national patents. Products are exported to South Korea, India, Southeast Asia, Africa and other countries and regions.

Get A Quote

If you have any questions, please feel free to leave us a message at any time