Unlocking the Potential of Quality Quartz Powder Production Lines

Quality quartz powder production lines play a crucial role in various industries, including electronics, construction, and ceramics. Quartz is a versatile mineral known for its durability, chemical resistance, and ability to withstand high temperatures, making it an essential component in many applications. To achieve optimal performance in manufacturing quartz powder, it is vital to focus on the production line's design, equipment, and operational practices.

The first step in establishing a quality quartz powder production line is selecting appropriate raw materials. High-purity quartz sand is essential for producing superior quartz powder. The quality of the raw materials directly influences the final product's properties, including particle size, purity, and performance characteristics. Therefore, sourcing raw materials from reputable suppliers ensures consistency and reliability in production.

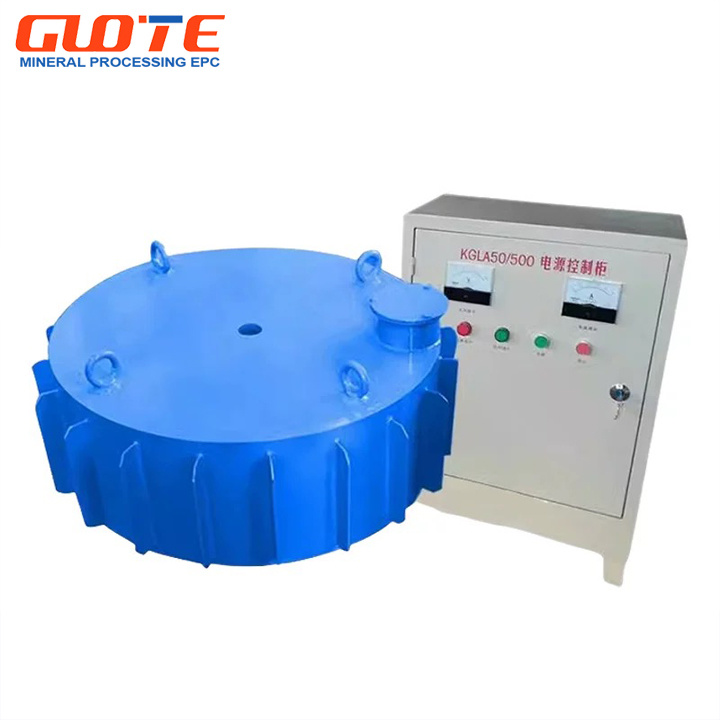

Next, the processing equipment used in the production line is critical. Key components typically include crushers, ball mills, air classifiers, and packaging systems. Each piece of equipment plays a specific role in transforming raw quartz into fine powder. For instance, crushers break down larger quartz chunks, while ball mills further grind the material to achieve the desired particle size. Air classifiers then separate particles based on size, ensuring that the final product meets the required specifications.

Moreover, maintaining a controlled environment during production is essential for achieving high-quality quartz powder. Factors such as temperature, humidity, and dust control should be monitored closely. Implementing advanced automation and monitoring systems can significantly enhance the efficiency of the production line. These systems can provide real-time data, allowing for quick adjustments and minimizing production downtime.

Another critical aspect is quality control. Regular testing of the quartz powder at various stages of production helps identify potential issues early on. This can include assessments of purity, particle size distribution, and other relevant parameters. Implementing a robust quality management system ensures that the final product meets industry standards and customer expectations.

Furthermore, training personnel involved in the production process is vital to maintaining high standards. Skilled operators are better equipped to handle equipment, troubleshoot issues, and optimize production settings. Investing in employee training programs can lead to increased efficiency and improved product quality.

In conclusion, establishing a quality quartz powder production line requires a comprehensive approach that encompasses raw material selection, equipment choice, environmental control, and ongoing quality assurance. By focusing on these elements, manufacturers can enhance their production capabilities and effectively meet the growing demand for high-quality quartz powder in various applications.

The first step in establishing a quality quartz powder production line is selecting appropriate raw materials. High-purity quartz sand is essential for producing superior quartz powder. The quality of the raw materials directly influences the final product's properties, including particle size, purity, and performance characteristics. Therefore, sourcing raw materials from reputable suppliers ensures consistency and reliability in production.

Next, the processing equipment used in the production line is critical. Key components typically include crushers, ball mills, air classifiers, and packaging systems. Each piece of equipment plays a specific role in transforming raw quartz into fine powder. For instance, crushers break down larger quartz chunks, while ball mills further grind the material to achieve the desired particle size. Air classifiers then separate particles based on size, ensuring that the final product meets the required specifications.

Moreover, maintaining a controlled environment during production is essential for achieving high-quality quartz powder. Factors such as temperature, humidity, and dust control should be monitored closely. Implementing advanced automation and monitoring systems can significantly enhance the efficiency of the production line. These systems can provide real-time data, allowing for quick adjustments and minimizing production downtime.

Another critical aspect is quality control. Regular testing of the quartz powder at various stages of production helps identify potential issues early on. This can include assessments of purity, particle size distribution, and other relevant parameters. Implementing a robust quality management system ensures that the final product meets industry standards and customer expectations.

Furthermore, training personnel involved in the production process is vital to maintaining high standards. Skilled operators are better equipped to handle equipment, troubleshoot issues, and optimize production settings. Investing in employee training programs can lead to increased efficiency and improved product quality.

In conclusion, establishing a quality quartz powder production line requires a comprehensive approach that encompasses raw material selection, equipment choice, environmental control, and ongoing quality assurance. By focusing on these elements, manufacturers can enhance their production capabilities and effectively meet the growing demand for high-quality quartz powder in various applications.

quality Quartz powder production line

Previous Page

Previous Page

Related Products

Related News