Unlocking Efficiency: Exploring the Best Vibrating Dewatering Screens

Vibrating dewatering screens play a pivotal role in the filtration and separation processes, particularly in the mining, aggregate, and recycling industries. These machines are designed to remove excess moisture from materials, which is essential for improving product quality and processing efficiency. An effective dewatering screen utilizes vibration to ensure the material is both separated and dried, effectively increasing throughput while minimizing the need for additional drying processes.

One of the primary benefits of using a vibrating dewatering screen is its efficiency. The vibration mechanism effectively loosens and stratifies the material, allowing water to drain more rapidly. This leads to a drier end product, which not only reduces transportation costs but also enhances the performance of downstream processes. Additionally, a well-designed vibrating dewatering screen can handle a variety of materials, including sand, gravel, and sludge, making it a versatile choice for numerous applications.

When considering the best vibrating dewatering screen for your needs, it's essential to focus on several key features. Firstly, the screen's construction materials should be durable and resistant to wear and tear, as the screening process can be abrasive. High-quality wire mesh or polyurethane panels are often recommended for their longevity and efficiency in separating materials.

Another critical aspect is the screen's inclination angle. The angle of the screen can significantly affect the drainage rate and overall performance. A steeper angle may facilitate faster drainage, but it can also impact the material's movement across the screen. Therefore, optimization of the angle based on the material properties and desired outcomes is crucial.

Moreover, the excitation force and frequency of the vibrations can also play a vital role in the machine's effectiveness. Different materials respond uniquely to varying vibration patterns, so selecting a screen with adjustable settings can provide better adaptability to specific processing needs.

In conclusion, the best vibrating dewatering screens are those that combine durability, efficiency, and versatility. By understanding the critical features and benefits of these machines, businesses can make informed decisions that enhance their operational efficiency and product quality. Investing in the right vibrating dewatering screen can be a game-changer in achieving optimal results in material processing and separation.

One of the primary benefits of using a vibrating dewatering screen is its efficiency. The vibration mechanism effectively loosens and stratifies the material, allowing water to drain more rapidly. This leads to a drier end product, which not only reduces transportation costs but also enhances the performance of downstream processes. Additionally, a well-designed vibrating dewatering screen can handle a variety of materials, including sand, gravel, and sludge, making it a versatile choice for numerous applications.

When considering the best vibrating dewatering screen for your needs, it's essential to focus on several key features. Firstly, the screen's construction materials should be durable and resistant to wear and tear, as the screening process can be abrasive. High-quality wire mesh or polyurethane panels are often recommended for their longevity and efficiency in separating materials.

Another critical aspect is the screen's inclination angle. The angle of the screen can significantly affect the drainage rate and overall performance. A steeper angle may facilitate faster drainage, but it can also impact the material's movement across the screen. Therefore, optimization of the angle based on the material properties and desired outcomes is crucial.

Moreover, the excitation force and frequency of the vibrations can also play a vital role in the machine's effectiveness. Different materials respond uniquely to varying vibration patterns, so selecting a screen with adjustable settings can provide better adaptability to specific processing needs.

In conclusion, the best vibrating dewatering screens are those that combine durability, efficiency, and versatility. By understanding the critical features and benefits of these machines, businesses can make informed decisions that enhance their operational efficiency and product quality. Investing in the right vibrating dewatering screen can be a game-changer in achieving optimal results in material processing and separation.

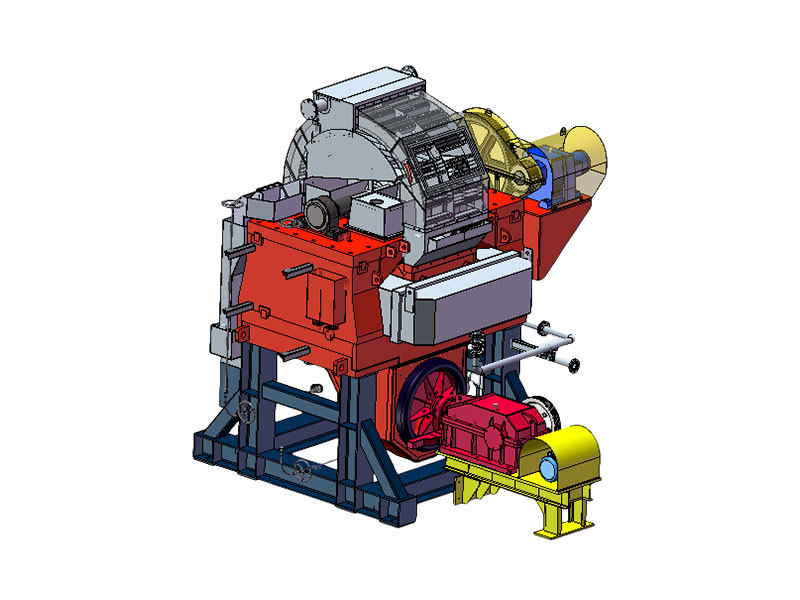

best Vibrating Dewatering Screen

Related Products

Related News