Unlocking the Potential: A Comprehensive Guide to Ilmenite Processing Line

Unlocking the Potential: A Comprehensive Guide to Ilmenite Processing Line

Table of Contents

- 1. Introduction to Ilmenite and Its Importance

- 2. What is Ilmenite?

- 3. Properties of Ilmenite

- 4. The Ilmenite Extraction Process: Techniques and Methods

- 5. Understanding the Ilmenite Processing Line

- 6. Benefits of Efficient Ilmenite Processing

- 7. Applications of Processed Ilmenite

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to Ilmenite and Its Importance

Ilmenite, a titanium-iron oxide mineral, is a critical source of titanium dioxide, which is extensively used as a pigment in paints, plastics, and paper. Its extraction and processing have become increasingly important due to the growing demand for titanium in aerospace, automotive, and medical applications. Understanding the ilmenite processing line not only highlights the mineral’s economic significance but also showcases the technological advancements employed in its extraction and refinement.

2. What is Ilmenite?

Ilmenite is composed of iron, titanium, and oxygen and is typically found in igneous rocks. It forms as a result of magmatic differentiation and is often associated with other minerals such as magnetite, zircon, and garnet. The chemical formula for ilmenite is FeTiO₃, indicating its iron and titanium content. Its shiny, metallic luster gives it the distinguishing characteristics sought after in mineralogy.

3. Properties of Ilmenite

Ilmenite possesses several unique properties that make it a valuable mineral:

3.1 Physical Properties

- **Color**: Black to brownish-black, with a metallic luster.

- **Hardness**: Ranges from 5 to 6 on the Mohs scale, indicating moderate toughness.

- **Density**: High density, typically around 4.6 g/cm³, making it relatively heavy for its size.

3.2 Chemical Properties

- **Stability**: Ilmenite is chemically stable under a range of environmental conditions, making it ideal for various industrial uses.

- **Reactivity**: Exhibits moderate reactivity, which is crucial in processes such as smelting and chlorination.

4. The Ilmenite Extraction Process: Techniques and Methods

The extraction of ilmenite can be divided into several key stages:

4.1 Mining Methods

Ilmenite is primarily extracted through open-pit mining or seabed mining. Open-pit mining involves removing overburden to access ilmenite-rich deposits, while seabed mining utilizes specialized equipment to dredge the seabed for ilmenite.

4.2 Crushing and Grinding

Once extracted, ilmenite ore is crushed and ground to liberate the mineral from associated materials. This step is crucial for maximizing recovery rates in subsequent processing stages.

4.3 Separation Techniques

Various separation techniques are employed to isolate ilmenite from impurities. Common methods include:

- **Magnetic Separation**: Utilizing magnetic fields to separate magnetic minerals from non-magnetic ones.

- **Gravity Separation**: Exploiting differences in specific gravity to separate ilmenite from lighter materials.

4.4 Smelting Process

The smelting process involves heating ilmenite with carbon in the presence of a flux, resulting in the production of titanium dioxide and iron. This step is essential for refining the mineral into a usable form.

5. Understanding the Ilmenite Processing Line

An effective ilmenite processing line consists of several integrated stages designed to enhance efficiency and output quality.

5.1 Pre-Processing Stage

This initial stage includes the preparation of raw ilmenite, which involves crushing, grinding, and initial separation. The aim is to achieve a consistent particle size for optimal processing.

5.2 Processing Technology

Modern processing lines utilize advanced technology for maximum yield. Techniques such as **hydrometallurgy** and **pyrometallurgy** are employed to extract titanium from ilmenite, ensuring high purity levels.

5.3 Quality Control Measures

Implementing quality control measures throughout the processing line is crucial. Regular testing for impurities and adherence to industry standards ensures that the final product meets market demands.

6. Benefits of Efficient Ilmenite Processing

Efficient ilmenite processing offers numerous advantages:

6.1 Economic Benefits

Enhanced processing techniques lead to higher recovery rates and reduced operational costs, boosting profitability.

6.2 Environmental Sustainability

Modern processing methods prioritize environmental sustainability by reducing waste and energy consumption. Techniques such as closed-loop systems minimize the ecological footprint of ilmenite processing.

6.3 Quality of End Product

High-quality ilmenite processing results in a superior end product with fewer impurities, enhancing its value and applicability across various industries.

7. Applications of Processed Ilmenite

Processed ilmenite has a wide range of applications, including:

7.1 Titanium Dioxide Production

The primary use of processed ilmenite is in producing titanium dioxide, a white pigment used in paint, coatings, and plastics.

7.2 Aerospace and Automotive Industries

Due to its lightweight and high strength, titanium extracted from ilmenite is extensively used in the aerospace and automotive sectors for manufacturing components that require durability and resistance to corrosion.

7.3 Medical Applications

Titanium, derived from ilmenite, is also utilized in medical implants and devices due to its biocompatibility and strength.

8. Frequently Asked Questions (FAQs)

8.1 What is the main use of ilmenite?

Ilmenite is primarily used for producing titanium dioxide, which is widely utilized in paints, plastics, and various industrial applications.

8.2 How is ilmenite processed?

Ilmenite is processed through several stages, including mining, crushing, grinding, separation, and smelting.

8.3 What are the environmental impacts of ilmenite processing?

While ilmenite processing can have environmental impacts, modern techniques are increasingly focused on sustainability, aiming to reduce waste and energy consumption.

8.4 Can ilmenite be used in construction?

Yes, processed ilmenite can be used in construction as a pigment and in the production of various building materials.

8.5 What are the challenges in ilmenite processing?

Challenges include managing impurities, ensuring efficient recovery rates, and minimizing environmental impacts during extraction and processing.

9. Conclusion

Ilmenite processing is a vital component of the titanium supply chain, with significant implications for various industries. By understanding the intricate processes involved, from extraction to application, stakeholders can appreciate the importance of ilmenite and the role it plays in modern technology. As demand for titanium continues to rise, optimizing the ilmenite processing line will be crucial for meeting market needs and ensuring sustainable practices in mineral extraction and processing.

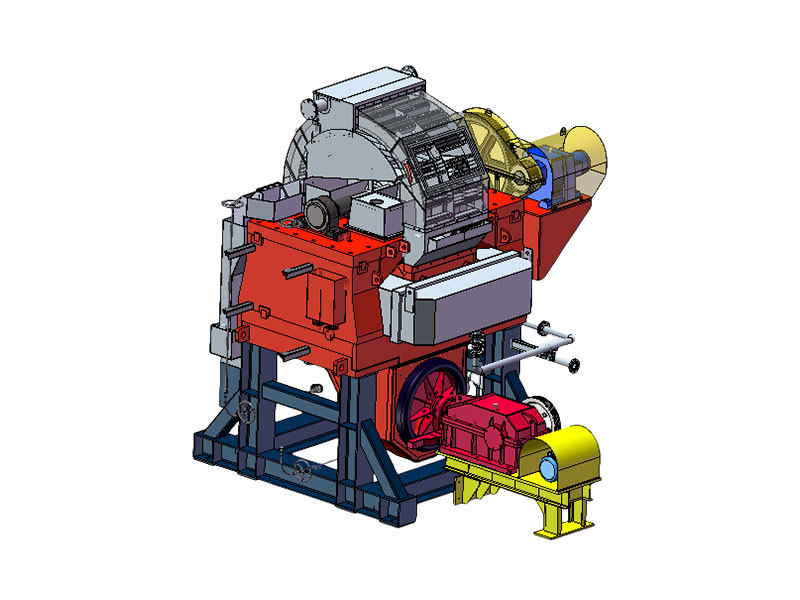

Ilmenite processing line

Related Products

Related News