Unlocking Efficiency: The Benefits of the Newest Drum Screen in Material Processing

Unlocking Efficiency: The Benefits of the Newest Drum Screen in Material Processing

Table of Contents

- 1. Introduction to Drum Screens

- 2. What is a Drum Screen?

- 3. Importance of Drum Screens in Material Processing

- 4. Benefits of the Newest Drum Screens

- 4.1 Enhanced Efficiency

- 4.2 Versatility and Adaptability

- 4.3 Cost-Effectiveness

- 4.4 Improved Productivity

- 5. Applications of Drum Screens in Various Industries

- 6. Maintenance and Care of Drum Screens

- 7. The Future of Drum Screens in Material Processing

- 8. Conclusion

- 9. FAQs

1. Introduction to Drum Screens

In the ever-evolving field of material processing, drum screens have emerged as pivotal components. Their ability to efficiently separate materials based on size and shape makes them indispensable in various industries, from mining to recycling. The newest drum screen technologies not only enhance performance but also introduce innovative features that contribute to overall efficiency and productivity.

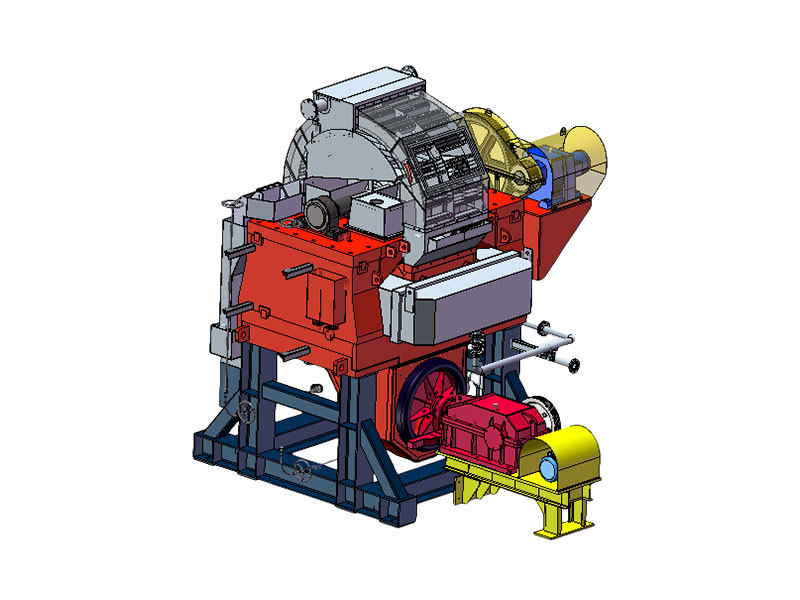

2. What is a Drum Screen?

A drum screen is a cylindrical device used in different material processing applications to separate and classify materials. It operates through a rotating drum that features perforated plates or mesh. As the drum rotates, materials are fed into one end and screened through the perforations, allowing smaller particles to fall through while larger ones continue to the other end. This mechanism is crucial for achieving optimal material separation, ensuring that only the desired sizes proceed for further processing.

3. Importance of Drum Screens in Material Processing

The importance of drum screens in material processing cannot be overstated. They are essential for:

- **Improving Material Quality**: By effectively separating materials, drum screens contribute to enhancing the quality of the final product.

- **Reducing Energy Consumption**: Efficient separation processes lead to lower energy usage, making operations more sustainable.

- **Minimizing Waste**: Proper screening ensures that only the desired materials are processed, reducing waste and lowering operational costs.

4. Benefits of the Newest Drum Screens

With technology advancing at a rapid pace, the latest drum screens offer numerous benefits that significantly improve their efficiency and effectiveness.

4.1 Enhanced Efficiency

The newest drum screens are designed with advanced features that increase throughput and reduce downtime. Innovations such as variable speed controls and automated cleaning mechanisms allow for continuous operation, ensuring that material processing is more streamlined than ever. The ability to adjust the speed based on the material type being processed contributes to maximizing efficiency.

4.2 Versatility and Adaptability

Modern drum screens are highly versatile, accommodating a wide range of materials, including aggregates, compost, and industrial waste. Their adaptability means they can be tailored to meet specific processing needs, making them ideal for various industries. This flexibility allows businesses to handle different inputs without the need for multiple machines, simplifying the material processing pipeline.

4.3 Cost-Effectiveness

Investing in the latest drum screens can lead to significant cost savings over time. With their enhanced operational features, these machines reduce the need for manual labor, lower maintenance costs, and decrease energy consumption. The long-term benefits of improved efficiency and reduced waste further enhance their cost-effectiveness, ensuring that companies get the most value from their investment.

4.4 Improved Productivity

The combination of enhanced efficiency and versatility translates directly into improved productivity. With the capability to handle larger volumes of material in a shorter time, businesses can increase their output without compromising on quality. This productivity boost is particularly beneficial in competitive markets where timely delivery and high standards are crucial.

5. Applications of Drum Screens in Various Industries

Drum screens are utilized across a multitude of industries, each benefiting from their unique capabilities. Key applications include:

- **Mining and Quarrying**: In these sectors, drum screens are essential for sorting stones and minerals efficiently.

- **Construction and Demolition**: They are used to separate recyclable materials from debris, promoting sustainability.

- **Waste Management**: Drum screens play a critical role in processing organic and inorganic waste, aiding in recycling efforts.

- **Agriculture**: Used for soil and compost processing, they help farmers enhance soil quality and promote better crop yields.

6. Maintenance and Care of Drum Screens

Maintaining drum screens is vital for ensuring their longevity and performance. Regular inspection, cleaning, and servicing are necessary to prevent breakdowns and optimize efficiency. Key maintenance practices include:

- **Routine Cleaning**: Keeping the drum and screens clear of debris prevents blockages and maintains optimal performance.

- **Regular Inspections**: Inspecting components for wear and tear helps in identifying potential issues before they escalate.

- **Lubrication**: Ensuring that moving parts are well-lubricated minimizes friction and extends the life of the equipment.

7. The Future of Drum Screens in Material Processing

As industries continue to embrace digital transformation, the future of drum screens will likely see further integration of smart technologies. Innovations such as IoT connectivity, AI-driven analytics, and automated monitoring systems are expected to enhance operational efficiency. These advancements will provide real-time insights into performance, allowing for proactive maintenance and optimization of processing workflows.

8. Conclusion

The latest advancements in drum screen technology are unlocking significant efficiencies in material processing. By enhancing operational performance, improving versatility, and reducing costs, modern drum screens serve as crucial tools for a variety of industries. As businesses increasingly seek to optimize their processes, investing in cutting-edge drum screens will not only enhance productivity but also ensure sustainability in material handling. Embracing these innovations is essential for staying competitive in the rapidly evolving landscape of material processing.

9. FAQs

What materials can be processed using drum screens?

Drum screens can process a wide range of materials, including aggregates, compost, industrial waste, and more, making them versatile for various applications.

How do drum screens improve efficiency?

They enhance efficiency by providing precise material separation, reducing downtime, and accommodating various material types without the need for multiple machines.

What maintenance is required for drum screens?

Regular cleaning, inspections, and lubrication are essential for maintaining drum screens and ensuring optimal performance.

Can drum screens be customized for specific applications?

Yes, modern drum screens can be tailored to meet the specific needs of different industries and materials.

What are the economic benefits of investing in a new drum screen?

Investing in new drum screens can lead to lower operational costs, improved productivity, and reduced waste, ultimately providing better value for businesses.

newest Drum screen

Related Products

Related News