Understanding the Manganese Ore Processing Line: A Key to Efficient Production

Manganese ore processing plays a significant role in the production of various materials, particularly in the construction industry. Manganese, a crucial element, is primarily used in steelmaking. The processing line for manganese ore involves several key stages, each designed to enhance the quality and yield of the final product.

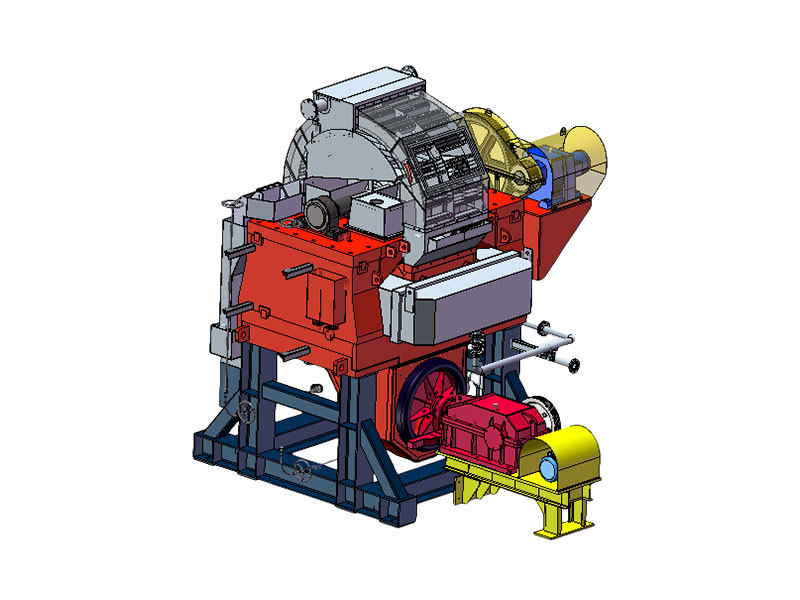

The first stage of manganese ore processing typically involves crushing and grinding. This initial step is essential for reducing the size of the ore and liberating the manganese minerals from the surrounding material. Several types of crushers may be utilized, including jaw crushers and cone crushers, depending on the characteristics of the ore. The grinding process then reduces the crushed ore to a fine powder, preparing it for further treatment.

Following size reduction, the next step is classification, where the ground material is sorted based on particle size and density. This process is vital for separating valuable manganese-rich particles from waste material. Various classification techniques, such as hydrocyclones and vibrating screens, can be employed to achieve optimal separation. A well-designed classification stage enhances the efficiency of the overall processing line.

Another crucial aspect of the manganese ore processing line is the concentration stage, which aims to increase the manganese content in the ore. This can be accomplished through methods such as gravity separation, flotation, or magnetic separation. Each method has its own set of advantages, depending on the ore type and the desired purity levels. For instance, gravity separation is suitable for materials with distinct density differences, while flotation may be utilized for finely disseminated manganese ores.

After concentration, the processed manganese ore may undergo further treatments, such as roasting or sintering, to improve its properties for steel production. These processes not only help in enhancing the quality of the manganese but also prepare it for subsequent manufacturing processes.

Environmental considerations are also paramount in the manganese ore processing line. Implementing efficient waste management practices and reducing energy consumption can significantly minimize the environmental impact of manganese processing. Companies are increasingly focusing on sustainable practices to ensure compliance with regulations and to contribute positively to their communities.

In conclusion, the manganese ore processing line is a critical component in the supply chain of construction materials, particularly in steel manufacturing. Understanding the stages involved, from crushing to concentration, enables manufacturers to optimize their operations and enhance product quality. Knowledge of the latest processing techniques and environmental considerations is essential for those in the manufacturing and processing machinery industry, ensuring that they remain competitive and responsible in today’s market.

The first stage of manganese ore processing typically involves crushing and grinding. This initial step is essential for reducing the size of the ore and liberating the manganese minerals from the surrounding material. Several types of crushers may be utilized, including jaw crushers and cone crushers, depending on the characteristics of the ore. The grinding process then reduces the crushed ore to a fine powder, preparing it for further treatment.

Following size reduction, the next step is classification, where the ground material is sorted based on particle size and density. This process is vital for separating valuable manganese-rich particles from waste material. Various classification techniques, such as hydrocyclones and vibrating screens, can be employed to achieve optimal separation. A well-designed classification stage enhances the efficiency of the overall processing line.

Another crucial aspect of the manganese ore processing line is the concentration stage, which aims to increase the manganese content in the ore. This can be accomplished through methods such as gravity separation, flotation, or magnetic separation. Each method has its own set of advantages, depending on the ore type and the desired purity levels. For instance, gravity separation is suitable for materials with distinct density differences, while flotation may be utilized for finely disseminated manganese ores.

After concentration, the processed manganese ore may undergo further treatments, such as roasting or sintering, to improve its properties for steel production. These processes not only help in enhancing the quality of the manganese but also prepare it for subsequent manufacturing processes.

Environmental considerations are also paramount in the manganese ore processing line. Implementing efficient waste management practices and reducing energy consumption can significantly minimize the environmental impact of manganese processing. Companies are increasingly focusing on sustainable practices to ensure compliance with regulations and to contribute positively to their communities.

In conclusion, the manganese ore processing line is a critical component in the supply chain of construction materials, particularly in steel manufacturing. Understanding the stages involved, from crushing to concentration, enables manufacturers to optimize their operations and enhance product quality. Knowledge of the latest processing techniques and environmental considerations is essential for those in the manufacturing and processing machinery industry, ensuring that they remain competitive and responsible in today’s market.

Manganese ore processing line

Related Products

Related News