Transforming Rigid Materials: The Role of Petroleum Fracturing Sand Processing Lines

Transforming Rigid Materials: The Role of Petroleum Fracturing Sand Processing Lines

Table of Contents

- Introduction to Petroleum Fracturing Sand and Processing Lines

- Understanding the Petroleum Fracturing Process

- The Importance of Fracturing Sand in Oil and Gas Extraction

- Key Components of Sand Processing Lines

- Innovative Sand Processing Technologies

- Benefits of Effective Sand Processing in the Industry

- Challenges in Sand Processing and Effective Solutions

- The Future of Petroleum Fracturing Sand Processing Lines

- Frequently Asked Questions

- Conclusion

Introduction to Petroleum Fracturing Sand and Processing Lines

In the modern oil and gas industry, the extraction of hydrocarbons from the earth involves complex processes. Among these, **petroleum fracturing**—commonly known as fracking—plays a crucial role. At the heart of this extraction technique lies **fracturing sand**, a specialized material that enhances the efficiency of the drilling process. In this article, we will explore the function of **petroleum fracturing sand processing lines** in transforming rigid materials into high-quality sand essential for successful extraction.

Understanding the Petroleum Fracturing Process

Petroleum fracturing is a method employed to increase the yield of hydrocarbons from underground reservoirs. This process involves injecting a mixture of water, sand, and chemicals at high pressure into rock formations. The primary objective is to create fissures within the rock, allowing oil and gas to flow more freely.

The critical element in this process is the **fracturing sand**. Its primary purpose is to prop open the newly created fissures, preventing them from closing once the pressure is released. This ensures a consistent flow of oil and gas to the surface, making it indispensable in modern drilling operations.

How Fracturing Sand is Sourced

Fracturing sand is typically sourced from high-purity silica sand deposits. The quality of the sand is essential, as it must possess specific characteristics such as roundness, size, and strength to effectively perform in high-pressure environments.

The Importance of Fracturing Sand in Oil and Gas Extraction

Fracturing sand plays several critical roles in oil and gas extraction, impacting efficiency and safety.

Enhancing Reservoir Connectivity

By propping open fractures, sand enhances connectivity between the reservoir and the wellbore, allowing hydrocarbons to flow more freely. This increased connectivity translates to higher production rates and improved recovery of resources.

Reducing Operational Risks

Using high-quality fracturing sand reduces the risk of formation damage during drilling. Properly sized and high-strength sand minimizes the potential for sand clogging and other operational issues, which can lead to costly delays and safety hazards.

Key Components of Sand Processing Lines

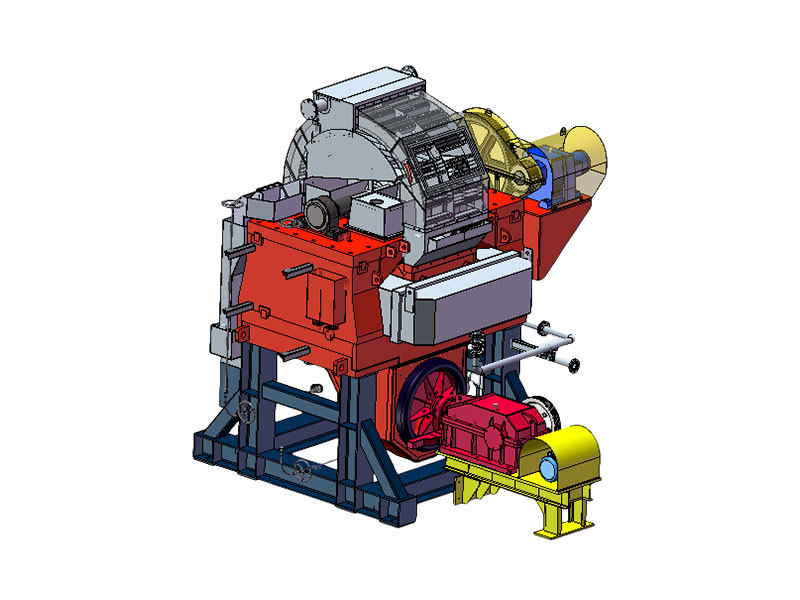

A typical petroleum fracturing sand processing line comprises several essential components that work together to transform raw materials into usable fracturing sand.

Crushing and Screening Equipment

The first step in processing sand involves crushing raw silica to break it down into smaller particles. Screening equipment then sorts these particles based on size, ensuring uniformity crucial for effective fracturing.

Washing and Classification Units

After crushing, the sand undergoes a washing process to remove impurities and unwanted materials. Classification units further separate the sand based on specific gravity, enhancing quality.

Drying Systems

Once washed, the sand must be dried to remove moisture. Drying systems play a crucial role in ensuring that the final product meets industry standards for performance and reliability.

Storage and Transport Systems

Finally, the processed sand is stored in silos or containers, ready for transport to drilling sites. Effective storage and handling systems ensure that the sand remains contamination-free until it is utilized in fracking operations.

Innovative Sand Processing Technologies

As demand for petroleum fracturing increases, so too does the need for innovative processing technologies. Several advancements are shaping the future of sand processing lines.

Automation and AI Integration

Automation technologies are enhancing efficiency in sand processing. Integrating AI allows for real-time monitoring and adjustments, improving productivity and reducing waste.

Advanced Material Handling Solutions

Innovative material handling solutions, such as conveyor systems and robotic sorting, streamline the processing line, ensuring faster and more efficient operations with reduced labor costs.

Environmental Considerations

More companies are adopting eco-friendly practices in sand processing. This includes water recycling systems and energy-efficient equipment that minimize environmental impact while maintaining output levels.

Benefits of Effective Sand Processing in the Industry

Effective processing of fracturing sand brings numerous benefits to the oil and gas industry.

Increased Extraction Efficiency

High-quality sand enhances the effectiveness of fracking operations, leading to increased extraction efficiency. This translates to higher output and profitability for companies.

Cost Reduction

Efficient processing lines reduce operational costs by minimizing waste and optimizing resource use. Furthermore, effective sand processing can lead to lower transportation expenses due to the reduced volume of wasted materials.

Improved Safety

With proper sand processing, the risks associated with pollution and contamination diminish. This contributes to safer working conditions for employees and compliance with environmental regulations.

Challenges in Sand Processing and Effective Solutions

While the benefits of effective sand processing are clear, several challenges persist within the industry.

Quality Control Issues

Maintaining consistent quality in sand production can be challenging. Implementing rigorous quality control measures at every stage of the processing line ensures that the final product meets industry standards.

Logistical Challenges

Transporting sand to remote drilling sites presents logistical hurdles. Investing in improved transportation infrastructure and utilizing advanced logistics software can streamline operations and address these challenges.

The Future of Petroleum Fracturing Sand Processing Lines

As the oil and gas industry evolves, so too will the technologies and processes associated with petroleum fracturing sand processing lines.

Technological Advancements

Continued investment in research and development will introduce new technologies that improve efficiency and sustainability in sand processing.

Market Trends

An increasing focus on sustainability will shape the future of sand processing. Companies are expected to prioritize eco-friendly practices, leading to innovations that balance profitability with environmental responsibility.

Frequently Asked Questions

1. What is fracturing sand?

Fracturing sand is a type of high-purity silica sand used in petroleum fracturing. It helps keep fractures in rock formations open during oil and gas extraction.

2. Why is the quality of fracturing sand important?

The quality of fracturing sand is crucial because it affects the efficiency of oil and gas extraction. High-quality sand ensures better connectivity in reservoirs, reducing operational risks.

3. How are petroleum fracturing sand processing lines structured?

Processing lines generally include crushing, screening, washing, drying, and storage systems, all designed to transform raw silica into high-quality fracturing sand.

4. What are the benefits of effective sand processing?

Benefits include increased extraction efficiency, reduced operational costs, and improved safety for workers and the environment.

5. What challenges do companies face in sand processing?

Common challenges include maintaining quality control, logistical issues regarding transportation, and the need for advanced processing technologies.

Conclusion

Petroleum fracturing sand processing lines are integral to the success of modern oil and gas extraction. By transforming rigid materials into high-quality sand, these processing lines enhance extraction efficiency, reduce operational risks, and pave the way for a more sustainable future in energy production. As technology continues to advance, the role of these processing lines will only become more critical, ensuring that the industry can meet rising demands while maintaining safety and environmental standards.

Petroleum fracturing sand processing line

Related Products

Related News