Unlocking the Benefits of RCYD Self-Discharging Permanent Iron Separators

Unlocking the Benefits of RCYD Self-Discharging Permanent Iron Separators

Table of Contents

- 1. Introduction to RCYD Self-Discharging Permanent Iron Separators

- 2. What is an RCYD Self-Discharging Permanent Iron Separator?

- 3. How RCYD Iron Separators Work

- 4. Benefits of Using RCYD Self-Discharging Permanent Iron Separators

- 4.1 Improved Operational Efficiency

- 4.2 Cost Reduction Strategies

- 4.3 Environmental Impact

- 4.4 Enhanced Material Quality

- 5. Applications of RCYD Self-Discharging Permanent Iron Separators

- 6. Technical Specifications and Features

- 7. Installation and Maintenance Guidelines

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to RCYD Self-Discharging Permanent Iron Separators

In the realm of manufacturing and material processing, the **efficiency** of operations is paramount. One of the critical components that can enhance this efficiency is the **RCYD Self-Discharging Permanent Iron Separator**. This sophisticated machine is designed to separate iron contaminants from bulk materials with minimal manual intervention. In this article, we will delve into the mechanics, benefits, applications, and maintenance of RCYD separators, illustrating how they can revolutionize your operations.

2. What is an RCYD Self-Discharging Permanent Iron Separator?

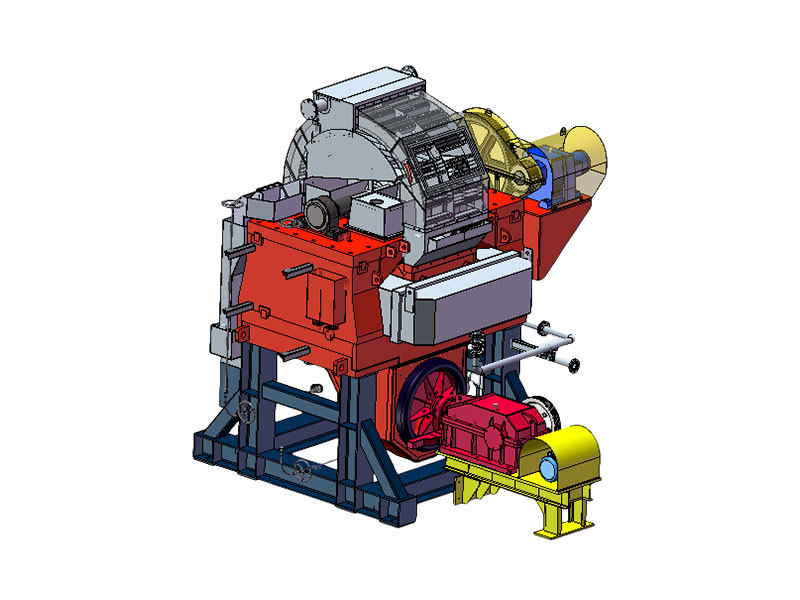

An **RCYD Self-Discharging Permanent Iron Separator** is a type of magnetic separator that utilizes permanent magnets to extract iron particles from materials such as grain, coal, and aggregates. Unlike traditional separators, the **self-discharging feature** allows continuous operation without the need for manual removal of collected iron, which significantly enhances productivity.

3. How RCYD Iron Separators Work

The functionality of the RCYD separator is straightforward yet effective. The system comprises a **magnetic roller** and a discharge mechanism. As the material passes over the magnetic roller, iron particles are attracted and held against the roller's surface. Once the material moves past the roller, a **self-discharging mechanism** releases the iron contaminants into a designated area. This process not only ensures thorough separation but also maintains the flow of material, preventing any bottlenecks during operation.

4. Benefits of Using RCYD Self-Discharging Permanent Iron Separators

Understanding the advantages of implementing **RCYD Self-Discharging Permanent Iron Separators** can guide you in enhancing your manufacturing processes. Here are some significant benefits:

4.1 Improved Operational Efficiency

RCYD separators drastically improve operational **efficiency** by reducing downtime associated with manual cleaning and maintenance. Their self-discharging capabilities allow for continuous material flow, ensuring that your processes run smoothly and without interruption.

4.2 Cost Reduction Strategies

Investing in RCYD iron separators can lead to substantial **cost savings**. By minimizing labor costs associated with manual separation, reducing wear on equipment, and improving material recovery rates, these separators provide a return on investment that can significantly affect your bottom line.

4.3 Environmental Impact

By effectively removing iron contaminants, RCYD separators contribute to a cleaner production process. They play a vital role in reducing waste generated from contaminated materials, thus promoting **sustainable manufacturing practices**. This environmental responsibility can also enhance your brand image and appeal to eco-conscious consumers.

4.4 Enhanced Material Quality

Maintaining high standards of material quality is essential in any manufacturing operation. RCYD separators excel at producing cleaner end products by eliminating unwanted iron impurities. This not only improves the overall quality of the material but also enhances its market value.

5. Applications of RCYD Self-Discharging Permanent Iron Separators

RCYD Self-Discharging Permanent Iron Separators find applications across various industries. Here are a few notable examples:

- **Food Processing:** Ensuring that food products are free from metallic contaminants is critical. RCYD separators facilitate this by effectively removing iron particles from grains and other food ingredients.

- **Construction and Mining:** In these industries, maintaining the integrity of raw materials is vital. RCYD separators help in purifying aggregates and ores, enhancing the quality of final products.

- **Recycling:** The recycling sector benefits from RCYD separators by efficiently sorting metals from waste materials, contributing to higher recycling rates and reduced landfill waste.

6. Technical Specifications and Features

When considering the implementation of RCYD Self-Discharging Permanent Iron Separators, understanding their technical specifications is crucial. Key features include:

- **Magnetic Intensity:** High magnetic intensity ensures effective iron separation.

- **Durability:** Built with robust materials, RCYD separators are designed to withstand harsh operating conditions.

- **Capacity:** Available in various sizes to accommodate different material flow rates and operational scales.

- **Ease of Installation:** Simple setup procedures allow for quick integration into existing production lines.

7. Installation and Maintenance Guidelines

Proper installation and regular maintenance are essential for maximizing the performance of RCYD separators. Here are some guidelines:

- **Installation:** Ensure that the separator is correctly aligned with the material flow direction. Follow the manufacturer's specifications for mounting and wiring.

- **Routine Maintenance:** Regularly inspect the magnetic roller for wear and clean the discharge mechanism to prevent blockages. Periodic checks ensure that the separator operates at peak efficiency.

8. Frequently Asked Questions

1. How does an RCYD separator differ from other magnetic separators?

RCYD separators are equipped with a self-discharging mechanism, allowing for continuous operation without manual intervention, unlike traditional magnetic separators that require frequent cleaning.

2. What materials can be processed with RCYD separators?

RCYD separators are versatile and can process various materials, including grains, coal, aggregates, and recycled materials.

3. Are RCYD separators energy-efficient?

Yes, RCYD Self-Discharging Permanent Iron Separators are designed for energy efficiency, utilizing permanent magnets that require no external power source for operation.

4. How often should maintenance be performed on RCYD separators?

Routine inspections should be conducted regularly, with thorough maintenance checks performed at least once every six months, or more frequently depending on usage intensity.

5. Can RCYD separators be used in outdoor environments?

While RCYD separators are built for durability, it is advisable to protect them from extreme weather conditions to ensure optimal performance and longevity.

9. Conclusion

RCYD Self-Discharging Permanent Iron Separators present a remarkable solution for enhancing operational efficiency, reducing costs, and improving material quality across various industries. Their advanced features and benefits make them a valuable investment for any manufacturing operation. By implementing these separators, businesses can not only streamline their processes but also contribute positively to environmental sustainability. As industries continue to evolve, the integration of such innovative technologies will be pivotal in achieving superior performance and maintaining competitive advantages.

RCYD self-discharging permanent iron separator

Related Products

Related News